Specialized Tarmac S-Works SL7 Fork Recall

DurianRider is reporting on his YouTube Channel that Specialized will be issuing a fork recall for the Tarmac SL7 series of bikes. Documents purported to have been leaked from Specialized have been shown on the channel and judging by the drawings and the CAD system used to produce them, they look to be genuine.

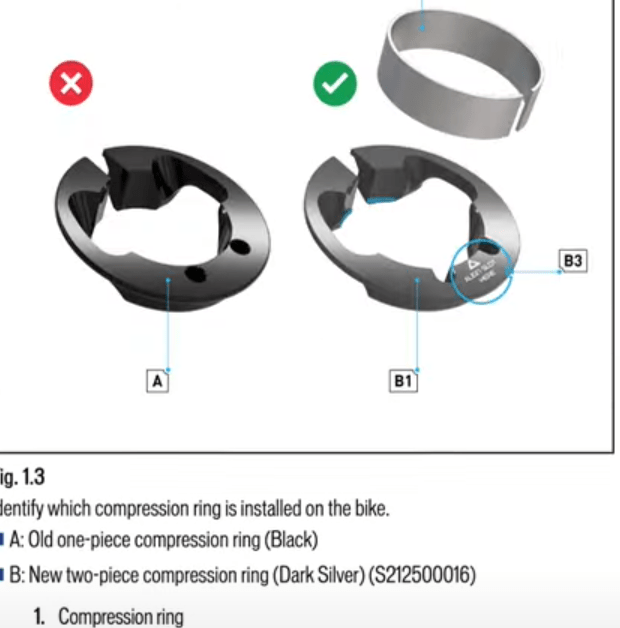

It would appear that Specialized have been using a compression ring with no chamfer and this has cut into the fork steerer assembly and this in turn creates a stress raiser which is prime for a crack and catastrophic failure. It is not clear how many failures have occurred.

If the compression ring minus the chamfer is true then this would be heaping embarrassment on the Californian company. Compression ring design is a basic level of engineering that even a first year engineering student would know let alone a multi-million dollar company employing the finest minds in the industry.

In the video, Durianrider shows the perceived level of damage that Specialized indicates is acceptable. One Hambini viewer sent in an image of his Specialized Fork Steerer which shows shows extensive fretting. The compression ring is typically steel (sometimes aluminium) and are much harder than carbon. Hence any micro fretting produces a characteristic track which gets worse with increased vibration.

Specialized have been a boutique brand for many years and prided themselves on their “engineering”. They have long claimed multiple stiffness increases and mega watt savings from their “Win” tunnel. Marketing that the cycling press are keen to highlight.

Ironically, Specialized recently released the CRUX gravel bike. It did not take long for internet users to suss out that it was simply an Aethos with wider tire clearance and a $12k price tag. The marketing claiming 100,000 iterations was largely ripped to shreds.

User Photographs Circulating on Social Media

Further photographs are circulating around Instagram

SL7 has been designed by German company Denk Engineering. Manufacturing is done by Topkey factory in Taiwan. Hard do say who is at fault. But it is very good that company does a recall, taking care of their consumers. Both you and Raoul Leuscher showed us many design flaws in carbon frames and forks. Yet very few companies corrected them.

I can’t disagree but it’s the most expensive bike you can buy, it leaves the factory with an unchamfered compression ring. What kind of engineering oversight is that?

Topkey is in China bro. SWORKS are Chinese made frames and forks. Taiwan is where they ship from and are assembled. Less tax this way. Source? Current and ex Specialized employees.

That is not true. Denk Engineering did the SL6 and likely will do the SL8. The SL7 was done by another crew as Denk was working on the Aethos/Crux as well as other MTB models.

More and more german companies produce more and more shitty parts. Recently ordered 10 flanges for vacuum – all 10 were out of spec for 0.2 mm each! The tech drawing provided by the company (emios technologies GmbH) differs from the actual part in 4 places! The true engineers are pretty old, and you may find them at Unis or institutes (Max Plank, Leibniz, Fraunhoffer societies). And even there it becomes a problem, as the young generation sometimes can not even properly read a tech drawing.

I love winding up SL7 owners with this recall

Their flagship bike reduced to a recall. Imagine all the dentists.

This is interresting. I had a warranty changed SL7 frame in May this year. And my stem already has this two-piece compression ring (B – on the shematic picture).

Same for our SL7… already the two-piece compression ring installed.

Appears to not have been tested properly ?

I have the old compression ring. Checked my steerer and no visible compression damage. I’ve put about 6,000 miles on it so far. However, my stem is relatively short and I’m a fairly light rider. Perhaps that makes a difference?

Absolutely no: I’m tall (61cm SL7 frame) and my stem is long with all the shims bellow it. I have absolutely no damages despite the old compression ring.

Does anyone know what the legal rights for a consumer are in this situation?

Would a consumer who purchased in the last 12 months be within their rights to request a refund?

This will vary depending on which country you live in.

U.K?

What about Venge? Doesnt the latest venge also have similar design? Why the venge is not on the recall list?

I asked the same thing to Specialized support. Here is their reply…

“Hello, thanks for reaching out and sorry to hear about your Venge’s brake lines. If you feel that the Venge is defective you will need to bring it to your local Specialized Retailer, with proof of purchase, and have them take a look at it. They will be able to let you know what your options are. To be clear, your Venge has a different fork, headset and stem from the SL7 and the issues that brought about our voluntary recall on the SL7 are not present on the Venge.

Good luck and happy riding!

-Nathan “

Basically they told me it’s not the same. Still doesn’t fix my brake line issue… lol.

I have one of the early s works SL7 with the first generation compression ring, i had mine apart anyway to pack for travel and there is zero markings on my steerer tube to indicate any damage. Bike is almost 1 year old and has been used hard on really bad surface roads since new.

As others have said it may be helped by the fact that I’m 65kg and have had the steerer cut down to only 1 spacer remining from day 1. I would imagine I am putting a lot less stress on that area than somebody twice my weight with a full compliment of spacers still in place.

Fun fact interview with Peter Denk from the german Tour Magazin:

“The fork breakages that have become known among professionals are only the tip of the iceberg; recreational riders also have their forks fall off. “A broken fork is the worst accident of all,” says engineer Peter Denk, who designs racing bikes for Specialized and looks back on a long career as a developer. “Every now and then, on a descent, I have the thought: What if the stem breaks off now?” Professionals are tough in this respect and see it as an occupational risk, he says. But he wants to avoid any risk: “I never want the stem of my bike to break under any circumstances. I do a lot of lightweight construction, but not on the steerer tube, I refuse to do that. I want this part to be over-engineered, so it gets extra layers – even though all the tests show that this is actually superfluous. I’ll accept the extra weight of 30 grams, but we’ll have to find it somewhere else.”

https://www.tour-magazin.de/service/ratgeber/wann-bricht-carbon-am-rennrad/a50426.html

I better call my dentist. One of his bikes might need to go in for a repair.

Such a simple solution to this. All owners need to get a file and do the chamfering themselves! They did not pay enough for their bikes so this is what they get

My bike doesn’t require a two piece compression ring to hold the stem on. I guess that’s because its not an overpriced heap of junk.