Engineering Bicycle Wheel Buyer’s Guide

Introduction

This buyer’s guide will allow you to make an informed choice about purchasing a set of new racing bicycle wheels. It has been written with elevated levels of technical content that should be at the level of most riders. Additional technical explanations are available elsewhere on the website.

Bicycle wheels are the best method of improving speed after the bike fit and clothing. They are not a trivial expense. In this current day and age, there are lots of different vendors of bike wheels and it is not practical to review every possible permutation. This guide will detail the things to look out for, avoid and ignore.

The Cycling Media

The cycling media, especially those with an online presence often do paid infomercials and generally repeat manufacturer’s data without any real objective numbers. Manufacturer’s themselves also provide data that is often misleading or designed to confuse. It is best to avoid these two sources in particular as their validity is questionable.

The basics – Tire and Braking device

The first thing to consider is the wheel and tire combination for your particular bike. This is partly a personal preference and partly frame characteristics. If the frame is limited to discs or rim brakes then that type of wheel is required.

A further consideration is the type of pneumatic system deployed.

Tire Type

Tubeless

A tubeless tire, A tubular tire or even a clincher tire are all widely used. Tubeless tires have touted advantages of having lower rolling resistance and improved puncture protection but living with them on a daily basis can be problematic. They can be difficult to seat. This type of tire requires a specific rim that is tubeless compatible.

Clincher

A clincher tire uses an inner tube and a tire that mounts into a hooked bead on the rim. This is by far the most popular choice and is relatively easy to install and maintain.

Tubular

This type of tire has long been the choice of racers, this has the lowest rolling resistance of any of the tire combinations. It can be time consuming having to deal with this on a daily basis and it is almost impossible to fix by the road side.

Braking System Type

Rim Brake

For braking systems, a conventional rim brake has been popular for many years and has been synonymous since the start of bicycle racing. This consists of a pair pads rubbing on the wheel rim to slow the bike down. On carbon rims, the performance in the wet can be delayed, however etched brake tacks such as those found on Farsports and Elite wheels make a considerable difference. High end groupsets from SRAM and Shimano have pushed Rim Brakes out of favour. Campagnolo and the upcoming brands from the far east continue to support Rim Brakes.

From an aerodynamic perspective, a rim brake is far superior to a Disc Brake. It does not incurr the peripheral drag of the centralized caliper on the fork and the pumping and turbulent mixing losses generated by the rotor slits.

Disc Brake

A carryover from the mountain bikes. Most new road bikes are being designed and/or fitted for hydraulic disc brakes. These brakes do offer significantly more braking power than a rim brake but it should be noted that the effective stopping power (and thus distance) is no better than a rim brake due to the limits in coefficients of friction. If all variables are kept the same, a disc brake bike will stop slightly later than a rim brake due to added weight.

A rim brake does not require reinforced wheel hubs, spokes or forks. A typical disc brake bike will weigh more than the equivalent rim braked counterpart.

The aerodynamic loss of the brake disc is not insignificant and a typical pumping/mixing loss is in the order of 10W at 220W of power output. The increased size of the brake hoods on STI levers also contribute to a Cd value that is worse for a Disc brake equipped bike.

The disc itself is designed to dissipate heat, it does this by generating turbulence. The generation of turbulence is an energy intensive process and this results in a pumping loss. A photo of Shimano brake discs is shown below, the glossy black sections are pumping vanes, they are designed to suck air from the centre of the disc and displace it outwards over the metallic portion of the braking surface, this reduces the skin temperature of the metal and prevents distortion. However this cooling results in a pumping loss.

Manufacturing

Most carbon wheels are made in China and more specifically in Xiamen. They are often sold as OEM rims to a western manufacturer who will package them together with hubs, apply their stickers and call it their own wheelset. Far eastern manufacturers are catching on to this and have started selling directly (Farsports, Winspace, Elitewheels, ICAN)

Some of the large western bike brands subcontract their manufacturing to OEM companies and specify the rim profiles, layups and resins used to make them. There can be quite significant differences in the quality of manufacturing.

An example of a well made rim is shown below, these are internal pictures of an Elite Drive Wheel.

The gallery below shows an Ascent Polaris wheel, an example of a poor wheel. There is excessive displacement of the carbon fibre layers that results in “tenting”, structurally the wheel would be weaker for a given thickness. “Tenting” is a colloquial term for a structural void.

Rim Depth – the key to Aerodynamic Gains

Aerodynamically and dynamically, the biggest differentiator between wheelsets is rim depth. The rim depth has a direct influence on the aerodynamics of the wheelset and the accumulated weight at large radii will have a direct influence on how fast you can accelerate, turn and brake the bike. That weight also affects the ride quality in terms of something called noise vibration and harshness. A good choice for a day in day out rim is 50mm, if you are time trialling then a rear disc with a 65mm front or deeper is a good choice. For Crit racing a 40mm size is recommended. In a crit, the rider needs the acceleration and is frequently riding in someone’s draft so the aero is not as important as the weight. Conversely in a time trial, the accelerations are limited so the aero is more important. Additionally if you are going up hills, a lighter wheel would be recommended.

The front wheel is far more sensitive to aerodynamic gains than the back wheel.

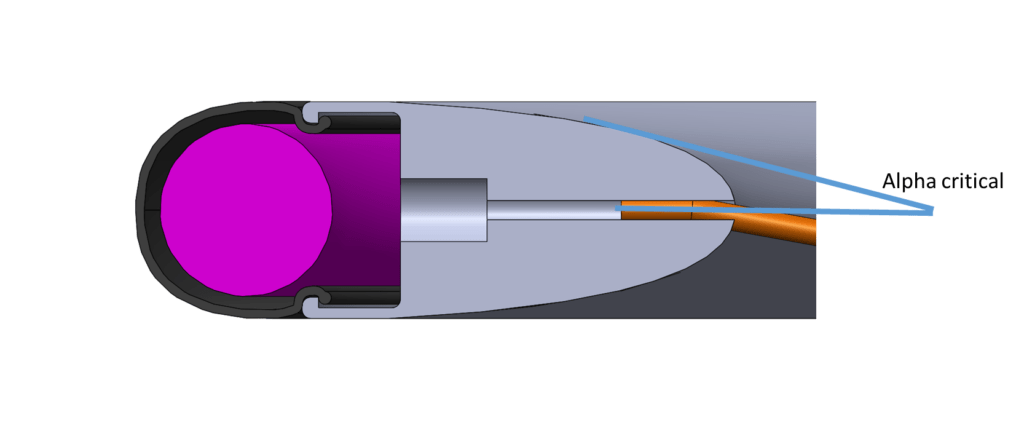

If all variables are kept largely the same, a deeper wheelset will always be more aerodynamic. This is mainly from a larger control area so the ability for air to mix and generate turbulence is reduced and a better alpha critical angle.

Alpha critical or alpha crit refers to the angle at which air leaves the body. A deeper wheel will generally have a shallower alpha critical angle.

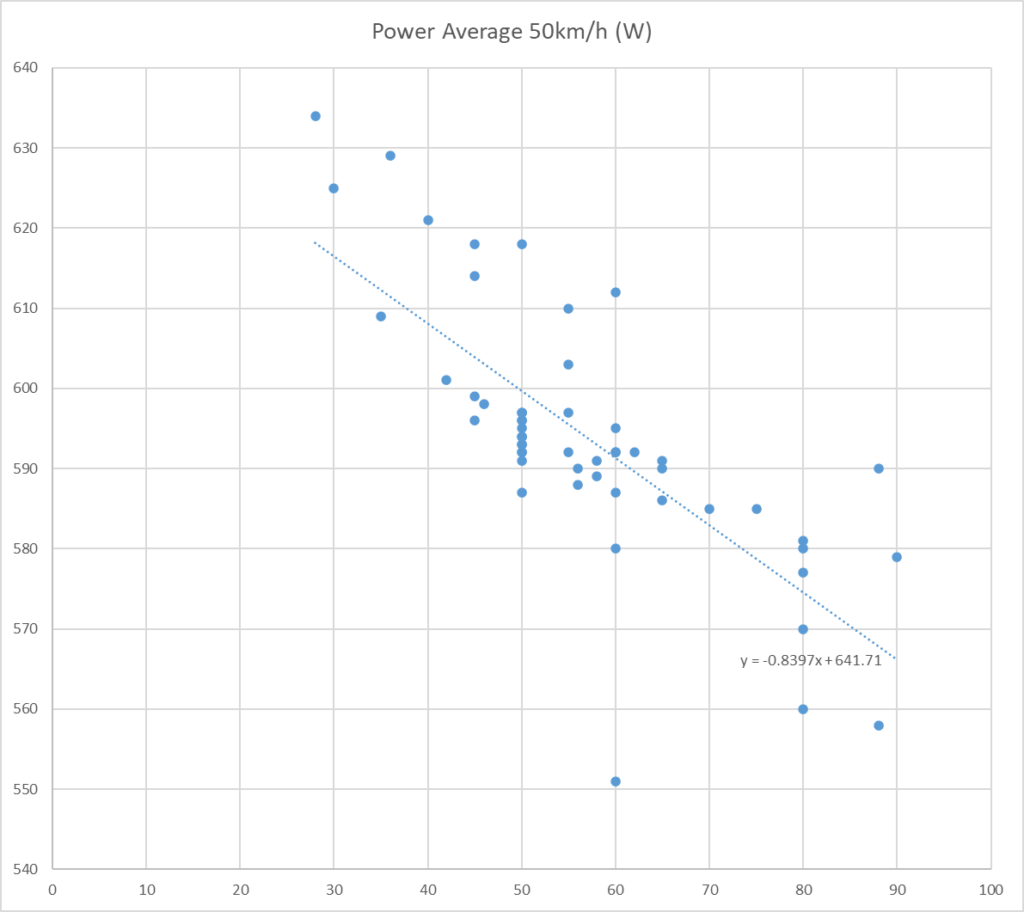

The graphs below show the correlation between rim depth plotted on the x axis and power absorbed on the y axis, they are at 50km/h and 30km/h. The relationship is quite clear, a deeper rim is faster. There are a few outliers but they generally follow the same pattern. A notable exception is the tri spoke wheel from farsports/aliexpress This is a fundamentally different concept and a large aerodynamic saving comes from the spokes (or lack of them) and the significant drop in mixing or pumping loss.

The same graph with the line of best fit plotted

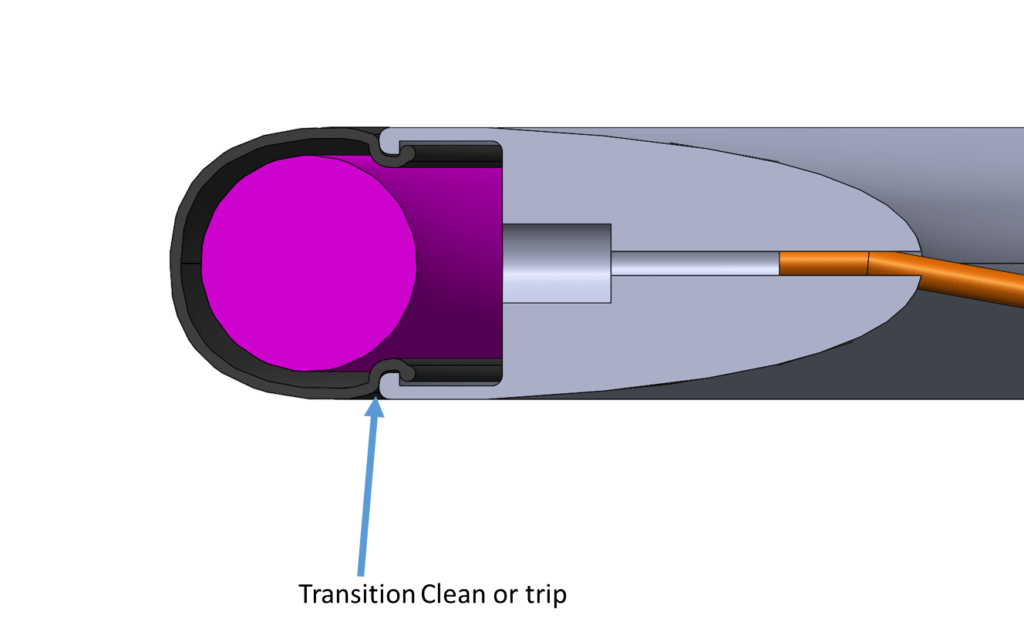

Rim Profile

There is not much to be gained from the rim profile in isolation but there are some factors that need to be looked at. Alpha critical has already been mentioned, the next most important consideration is the transition between the tyre and the rim. A smooth transition is beneficial in this area. Many people speak about the 105% rule to ensure the rim is 5% bigger than the tyre width. 105% is excessive, it is better to have the rim in line with the tyre ie 100%. If this isn’t possible then slightly bigger is better than lightbulbing. It’s a good idea to consider the tyre and rim as an assembly in this situation.

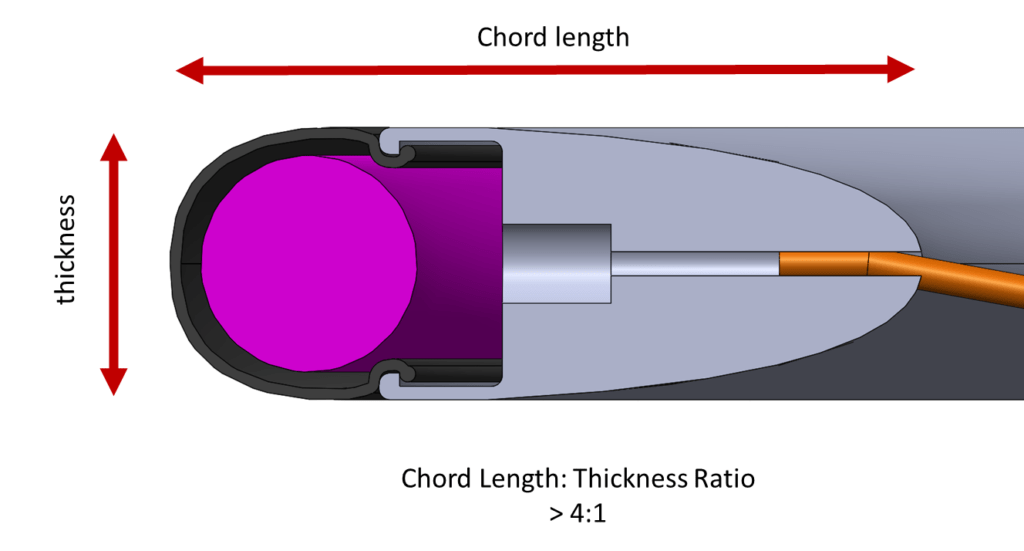

A rule of thumb, that is used frequently in aerospace is the 25% rule, a very tolerant and aerodynamic chord to thickness ratio is 4:1 and it is why NACA 0024 aerofoils are so well studied. The diagram below shows schematically how this relates to a wheel and tire combination. The tire must be included in the equation. Generally speaking for a tire that measures up at 23mm, a rim that is around 50mm deep would be required. That will give a thickness to chord ratio that exceeds the 4 to 1 ratio. if fitting a 28mm tyre, an additional 20mm of rim depth (ie a 70mm rim) to compensate for the additional thickness of the profile would be required.

As a side note, an increase in tire width will increase the ride height of the bike slightly.

The only real variations in rim profile away from the transition to the brake track tend to be around how blunt the trailing edge is. This is generally referred to as a toroidal rim profile or U shaped rim profile. Aerodynamically, aerofoils will have significant flow separation (colloquially called stall but technically not correct) at around 12 degrees. If the rider is going in a straight line, air is hitting them from around the 12 to 1 o clock position. The share is largely irrelevant (within reason), it will separate around the same number. A toroidal is not as aerodynamic as a pure teardrop shape but there are some structural challenges like attaching the spokes.

The advantage claimed by toroidal profiles is crosswind stability, this is a disputed area of aerodynamics. Crosswind instability or twitching is the result of pressure building on one side of the wheel (usually the front) and then suddenly collapsing. A toroidal is inherently less aerodynamic so that level of pressure build up is reduced but to be clear it is an aerodynamic penalty versus a teardrop type wheel of the same depth. Rim depth will have much more effect on the amount of twitching than the toroidal or non torodial nature. The twitching is a product of the pressure differential generated and the surface area exposed. A deeper rim has a squared relationship so just a small increase in rim depth has a dramatic increase in cross wind instability.

Stability is fairly controllable up to about 50mm rim depth, from there onwards, it becomes dramatically more unstable. This is evaluated by looking at the dinitriev performance of the wheelset. A winspace Hyper and an Elitewheels drive wheelset are shown below. The Winspace wheel is ultimately more aerodynamic but the dramatic change in crosswind stability that is largely dictated by depth is shown in the middle of the graph.

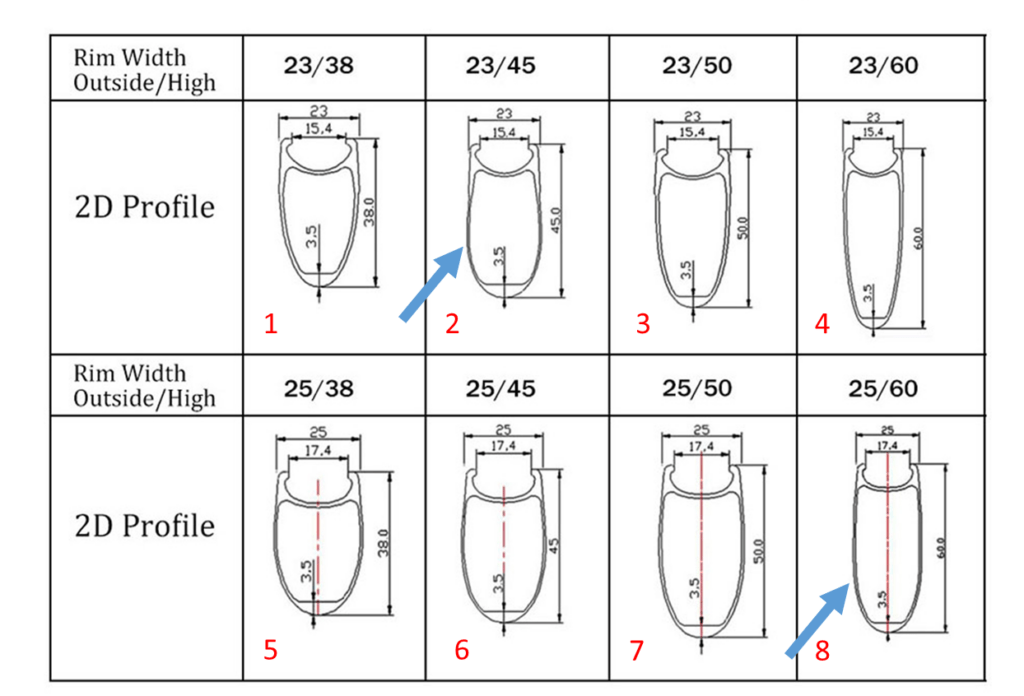

A lot of wheels are bought purely on rim profiles, the schematic below shows some popular variations

A blunter trailing edge will lead to worse ultimate aerodynamic performance because separation occurs further up the camber and causes a bigger wake. It is advisable to avoid wheels that have “late bulge” aerofoils, these sections are highlighted as items 2, 7 and 8. A superior section would be 1 and 4, these two sections have much shallower alpha critical angles and move profile 4 moves towards the 4:1 rule.

Spokes and Nipples

Fewer spokes that are wider will be faster, some popular types are SAPIM CX ray, Pilar Wing and a recent trend towards carbon fibre spokes. If the chosen spokes are to be carbon, be sure to check to make sure they have a mechanical taper lock design and not solely on adhesive. There have been widespread reports of the spokes from Ascent and KPS failing, resulting in crashes – Farsports, Winspace and Elite use a reverse taper design and are immune to this type of failure.

Hubs

Ratcheting System (Engagement points)

A major selling point is the number of engagement points and this is misleading. On a road bike, the gear ratios are such that a very fine ratchet engagement is rarely required.

Generally, the ratchet part of the assembly will not make an appreciable difference because it is only functioning when freewheeling. On load, the more important characteristic is rolling friction and associated hub stiffness. There can be quite a lot of flex generated in the hub from the bearing clearance.

The most common type of ratchet assembly is centrifugally acting which is shown below

An alternative system that has been adopted primarily by DT swiss is a sliding clutch ring. This is shown below

Bearing Setup

There are really only two designs of hubs, those that use loose angular contact bearings (cup and cone bearings), which is essentially Shimano and everybody else who uses deep groove ball bearings. Deep groove ball bearings are colloquially called cartridge bearings.

The big disadvantage with cup and cone is that once the mating surfaces wear out, it is not easy to replace them and essentially a new hub is required. The bearings will eventually wear out, irrespective of what you might read on the internet. These can be problematic to set up as they are very sensitive to preload. Drag tends to be higher on Shimano hubs than deep groove hubs.

Hubs using deep groove ball bearings vary quite considerably. It is advantageous to get a hub with the largest bearings available. The largest practical size is a hub that uses a 17mm bore bearing or bearings that end in 03 such as 6903 and 6803. Some budget hubs such as those found in Hunt wheels and others use quite slender axles, this is marginally better for drag but mechanically, it is not recommended. If the bike uses disc brakes, the bearing loading on the front wheel is much higher than a rim brake as the brake load is offset, it would be advisable to get a front hub with a large bearing. A 6903 would be a suitable choice.

Fits and Alignment

The rolling friction is adversely affected by the fit and alignment of the bearings inside the enclosures. There have been many reports and even videos on YouTube of eccentric bearing arrangement, this will increase power loss (see this example about HUNT). It is generally impossible to check this before buying the hubs so it’s worthwhile reading some reviews first. Reviews from existing riders rather than magazines are better in this case.

It is advisable to avoid any hub that uses a non DIN or ISO standard bearing. Some hubs from the likes of DT swiss and others use bearings that have (for example) 15267 or 18307 bearings in them. The bearings will inevitably wear out and this severely restricts your opportunities for replacement and as such they are not recommended.

Stainless Steel Bearings

One of the common failure modes for bearings is corrosion and this attracts people to stainless steel bearings. Stainless steel will still corrode but it will take much longer and a harsher chemical environment to do it. The disadvantage is they have much higher rolling friction and are softer than hardened steel bearings (52100), they tend to deform and if severe contamination into the bearing is experienced, it will cause galling. Riders that like like to sprint a lot, would be advised to avoid Stainless Steel Bearings.

Some large hub makers are Bitex, novatec, dt swiss, carbon ti.

What a cracking guide, thanks for taking the time to do this. It really helped my buying choice. I was in two minds over buying zipps or getting farsports. I went for the farsports and don’t regret it.

FWIW bicyclerollingresistance.com has (a) tubeless tires and (b) clinchers with latex tubes as both having lower rolling resistance than (c) tubulars. Only advantage of tubulars is reduced weight.

Based on my decades training and racing, clinchers are best for training and most racers. They are the least amount of hassle, and a good clincher tire on a top quality wheel is nearly as good as the best tubeless and tubular setups for most riders.

I’m inclined to agree with this. The others may be “technically superior” but from a hassle factor. I’d stick with clinchers and inner tubes.

I personally prefer hookless-tubeless and tyre liners. But all opinions are welcome. Ride on!

Thank you for the article!

Campag are cup loose angular contact bearing hubs too, though seem to run more smoothly for us than Shimano and cartridge bearing wheels we own with the exception of Mavic CCUs tubulars which have been the best.

Hi! sorry my english is not too good.

please help to understand the conclusion:

pawl is better than Ratchet,so if i want to buy wheel,dont choose dt swiss pr1600? pr1800 is better because it have pawl? or should i choose another wheel?(fulcrum racing 5 or 4?

(i have rimbrake al roadbike,tt speed on flat is 36-38km/h

Thank you for your analysis, Hambini!

Would you care to talk someday about the wheel wobble at high speeds?

I’m experiencing this wobble on my front wheel when descending at speeds over 60km/h and I can’t really put my finger on it: is it the wheel, is it the frame, is it my position/weight distribution, is it the tire/a combination of these? It helps a bit if I keep pedaling, it doesn’t help that much if I press my knees against the frame.

Usually it’s resonance that is causing it. I would suggest balancing your wheels as a first step. Have a look at my guide.

Hi Hambini,

I have a question about wheel holding its speed; I’ve seen some online reviewer saying wheel A holds speed better than wheel B, where both have similar depth and weight; I even heard a shallower wheel like DT PRC Mon Chasseral, and Roval Terra CLX II holds the speed really well; which get me really confuse as I always thought deeper and heavier wheel holds it’s speed better. Is it due to profile design? and I’m curious what’s the main factor to have the wheel holds its speed (from a physics, design perspective instead of one’s feeling.

Thank you!

What about full disc rear wheels. Can you put a wider tire on it and not have negative effects? For example 23mm outer width rim and 28mm tire?