ComePLAY Titanium Handlebars vs Aluminium vs 500T Press

Introduction

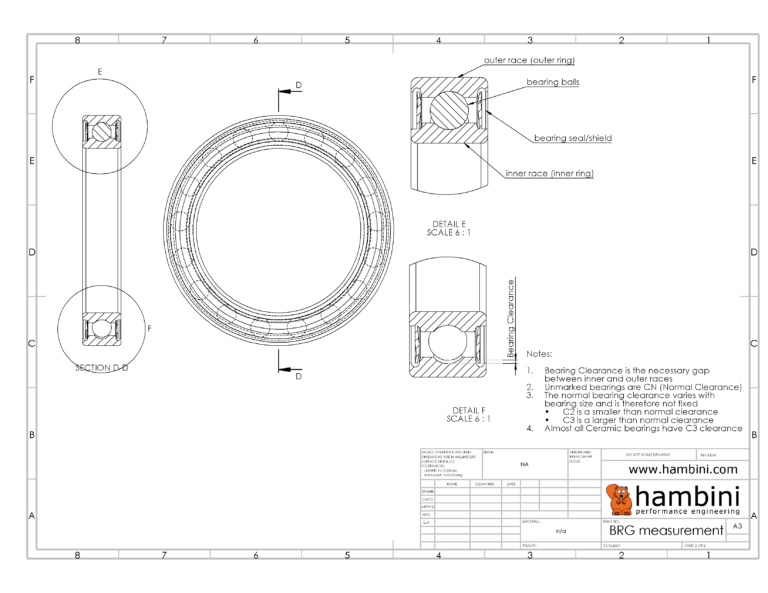

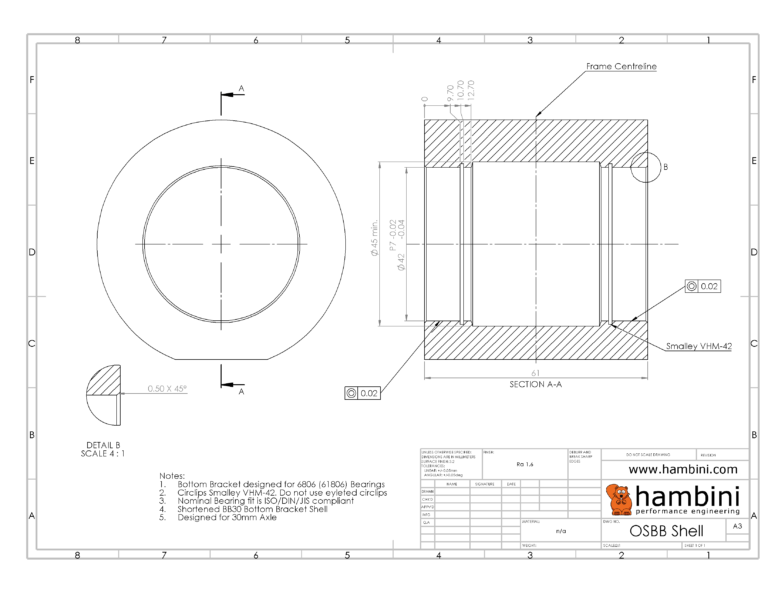

A viewer of the Hambini Youtube channel was on the lookout for some new titanium handlebars for his bicycle and found a Chinese company called Comeplay which specializes in titanium production. The handlebars retail at $180 and are available in a range of sizes and angles to accommodate most user requirements

There are a lot of choices when it comes to bike handlebars. You can go with aluminium, carbon fibre, or even titanium. So why choose Titanium? Titanium is strong and lightweight, making it the perfect choice for handlebars. Comeplay Titanium Handlebars are some of the strongest on the market (see below) and cheap too!

Handlebar Materials

Aluminium is by far the most popular choice for handlebar materials. Caron fibre is lightweight and comes with a significant cost increase. By comparison, Titanium has been prohibitively expensive.

Titanium

Titanium is a strong, lightweight metal that has many desirable properties. It is used in a variety of applications, from motorsport to aerospace. Titanium is known for its high strength-to-weight ratio, making it a popular choice for many products. It is also corrosion-resistant and non-toxic, making it a safe choice for many products. Titanium is an excellent choice for products that need to be strong and lightweight.

Aluminium

6061 Aluminium is strong for its weight. It has a yield strength of about 240MPa 38,000 pounds per square inch (psi). This means that it can be bent or stretched until it reaches 240MPa without breaking. Aluminium also has a tensile strength of about 290MPa 45,000 psi, meaning it can be pulled until it reaches 45,000 psi without breaking. These strengths make aluminium a good choice for parts that need to be strong yet lightweight.

Carbon Fibre

Carbon fibre composites are widely used in the aerospace, automotive, and sporting goods industries because of their high strength-to-weight ratios. The carbon fibres are extremely strong and stiff, while the resin matrix is relatively lightweight. This combination results in composites that are up to five times stronger than steel and twice as stiff. However, the resin matrix can also be brittle, so care must be taken during fabrication and handling to avoid damage.

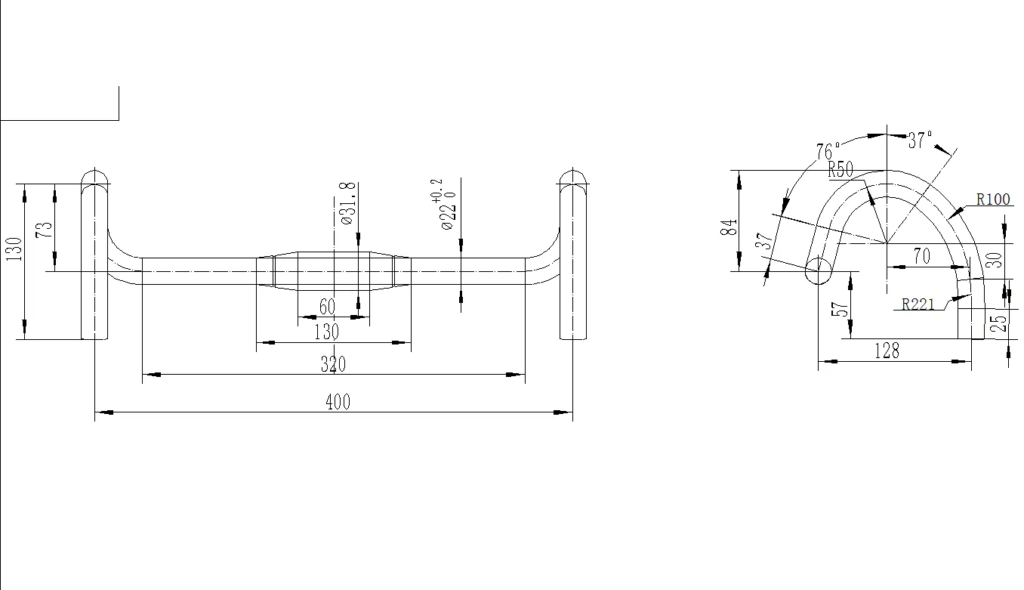

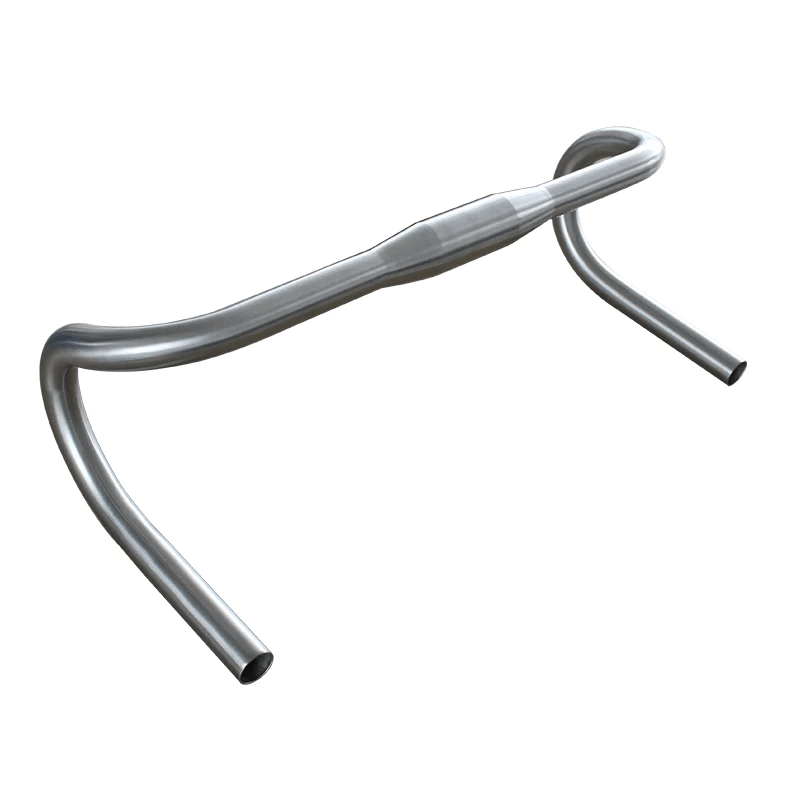

Handlebar Geometry

Handlebars are semi-made to order and standard sizes can be found off the shelf, whilst any amount of customization is available. In this case, the review sample had 42cm C-C with a central 31.8mm clamp diameter with a 1″ reduction in flaring towards drops which were formed by composite radial bends having differing radii.

The boundary geometry was generally very good, the ultimate centre of the handlebar drop end had a misalignment of approximately 2mm in the lateral direction. Following external consultation, this tolerance is considered to be excellent.

Handlebar Testing

Without a dedicated jig to test handlebars, it is quite difficult to ascertain the strength and stiffness between suppliers. Hence it was decided to subject a set of Aluminium handlebars and Titanium handlebars to some basic stiffness testing with a large hydraulic press. The test plotted the system pressure against the ram position.

This test did not look at the vibration damping (compliance) or comfort aspects of the handlebars as these elements are very much user preference.

Some photos during testing against an aluminium handlebar are shown below. Note the extensive flexion in the aluminium handlebar vs the ComePLAY Ti Handlebar

Photos of the creased structure are shown below

Analysis of Results

The Titanium handlebar is considerably stronger and stiffer than the aluminium handlebar. The Ti handlebar is over twice as stiff and when loaded beyond it’s elastic limit, it deforms locally. The aluminium handlebar has a much lower ultimate tensile stress and flexes quite quickly before sustaining a general buckling failure accompanied by a fracture of the bar. In contrast, the titanium handlebar suffered buckling of the skin.

It’s likely a rider would feel the reduced wind up (slack to take up the load) with the Ti Handlebar over the aluminium handlebar. This “feeling” is often perceived by cyclists to be the inherent stiffness.

Overall

There is a general thought amongst many people of poor quality emanating from Chinese manufacturers. There is little doubt that ComePLAY’s marketing would be considered to be borderline comical by western standards but their handlebars were found to be well-made, very stiff and extremely strong. The cost of $180 is very reasonable given the raw material cost. It is not difficult to recommend these handlebars.

The likelihood is most people will not notice the difference between titanium handlebars and aluminium handlebars from a structural perspective unless they are heavy or engaging in hard efforts like sprinting. The low wind up defelction is a nice benefit.

The handlebars do have a slight weight penalty although the unit which was tested is quite wide.

I am a fan of TI and own a couple of Ti bikes. However there is too much “fanboyism” about the material – its not some kind of magical element. In fact it is actually heavier than alu volume for volume – hence it only makes sense to replace (for weight saving) if parts can be made safely thinner. Clearly indicated by Hambini stating this handlebar is heavier than an alu equivalent. The custom hbar bending however is something I think would be a lucrative little niche. How many cyclists spend ridiculous amounts on custom geometry? Yet they will put up with very little genuine drop bar choice.

Ti is weaker than aluminum which is why aluminum is added to ti parts

This is a terrible and vague statement. EVERYTHING is an alloy–no one is building bikes with pure aluminum, either.

6066 aluminum alloy (used in many bike frames) is aluminum, silicon, magnesium, copper, and manganese.

7005 aluminum alloy add chromium, iron, titanium, zinc, and zirconium

Various grades of steel used in bicycle manufacturing are very, very different (witness the high tensile steel of cheapo frames versus something like Reynolds 853, which uses an alloy containing carbon, manganese, chrome, molybdenum, silicon, and copper). Similarly grade 1 or grade 2 titanium is very, very different from something like grade 9 (3/2.5) or grade 5 (6/4). That’s why the “noodly” quality of titanium bikes of the 1980s isn’t a thing anymore.

My experience with ComePLAY has not been positive so far. I placed my order for a handlebar 2 months ago and only received the automatic conformation email as communication from them. I reached out at one Month and received an email stating they would have a tracking number for me that weekend. Two weeks later I reached out again and received the same response but phrased differently. I’m gonna give them 2 more weeks then start action with PayPal to get my money back.