Bike Frame Manufacturing Standards

This story begins in Hall 9 of Eurobike, a key part of the exhibition that remains closed to the general public, reserved exclusively for industry insiders, professionals, and business representatives. Hall 9 serves as a behind-the-scenes marketplace where global manufacturers, often referred to as Original Equipment Manufacturers (OEMs), showcase their products and capabilities. These OEMs predominantly hail from the Far East, including China, Taiwan, and increasingly from emerging hubs such as India, Pakistan, and Bangladesh.

This hall represents the unseen engine of the cycling industry, where brands, retailers, and distributors come to negotiate, source, and establish partnerships. It’s a place that buzzes with business deals and technical discussions rather than the consumer-focused atmosphere seen in the main exhibition halls. Here, the stakes are higher, and the conversations more guarded, as companies seek to gain a competitive edge by leveraging the latest manufacturing innovations and cost-effective solutions from the East.

Many of these OEMs play a pivotal role in the global cycling market, producing not only complete bicycles but also frames, components, and accessories that are later branded and sold under various Western names. This is where much of the industry’s backbone is formed, far removed from the glossy brand marketing that the public sees. The allure of Hall 9 lies in its potential—OEMs set up stands that are less about flashy displays and more about business acumen, ready to entice Western brands with the promise of competitive pricing, scalable production, and custom manufacturing capabilities.

East Meets West

For companies in the West, Hall 9 offers a unique opportunity to directly engage with the source of their products, bypassing layers of middlemen and gaining firsthand insights into the latest advancements in manufacturing. This environment fosters a dynamic exchange of ideas and innovations, where product design, material science, and quality control are often discussed in depth.

The increasing presence of companies from India, Pakistan, and Bangladesh also highlights a shift in the global supply chain, as these regions are rapidly developing their manufacturing expertise and infrastructure to compete on the world stage. For many Western brands, this diversification of suppliers offers not just cost benefits but also the ability to mitigate risks associated with relying too heavily on a single geographic region.

In essence, Hall 9 is the nerve centre of the bike industry’s supply chain—a place where decisions made behind closed doors influence what consumers eventually see on the showroom floor. It’s a realm of strategic negotiations, technical expertise, and forward-thinking manufacturing, where the real work of bringing innovative cycling products to market begins.

For many years, there has been an ongoing debate about Chinese-made bicycles. Opinions are divided, with some critics dismissing them as substandard and unreliable, while others commend them for their high quality and competitive pricing. The truth lies somewhere in between, often depending on individual experiences and specific products.

This brings me to my visit to Hall 9 at the recent bike expo, where an unexpected conversation provided me with insights equivalent to 15 years of industry experience. It was a moment of clarity that confirmed some of my previous thoughts and offered a deeper understanding of the complexities involved in bicycle manufacturing.

I was in the market for a new frame to feature on my channel as part of a budget-friendly build project. After researching various options, I decided on a frame from Lightcarbon, a brand known within cycling circles for offering budget frames that deliver surprising performance.

At their stand, I met the head of Lightcarbon, who was present and eager to engage with visitors. Rather than simply delivering a sales pitch, he provided a comprehensive explanation of how their Original Equipment Manufacturers (OEMs) produce frames, highlighting the intricacies of the materials used, the manufacturing processes, and the quality control measures in place.

He discussed the specifications of their frames and elaborated on the importance of Quality Assurance (QA) and Quality Control (QC) procedures, detailing how these processes ensure the reliability and safety of their products. His transparency was refreshing; he openly acknowledged the challenges in the industry, including the variations in manufacturing standards across different factories. He emphasized that the key to a superior product lies in partnering with the right manufacturers who maintain high standards of quality and oversight.

This conversation validated many of my previous observations. It underscored the reality that quality variability is not exclusive to Chinese manufacturing but is a global concern. It also reinforced the idea that, with proper quality control and oversight, Chinese frames can offer exceptional value, sometimes exceeding expectations for their price point.

After my discussion at the Lightcarbon stand, I felt reassured in my decision to choose their frame for my project. It became clear that selecting a frame involves more than just aesthetics or cost considerations; it requires an understanding of the manufacturing process and the quality embedded in the product.

For anyone considering a bicycle frame from a lesser-known brand, especially one produced in China, it is crucial to look beyond superficial reviews. Engaging with the manufacturers and understanding their commitment to quality can provide invaluable insights, leading to more informed decisions. My experience at Hall 9 was a reminder that knowledge and transparency can transform a simple purchase into an informed and confident choice.

Quality Assessment

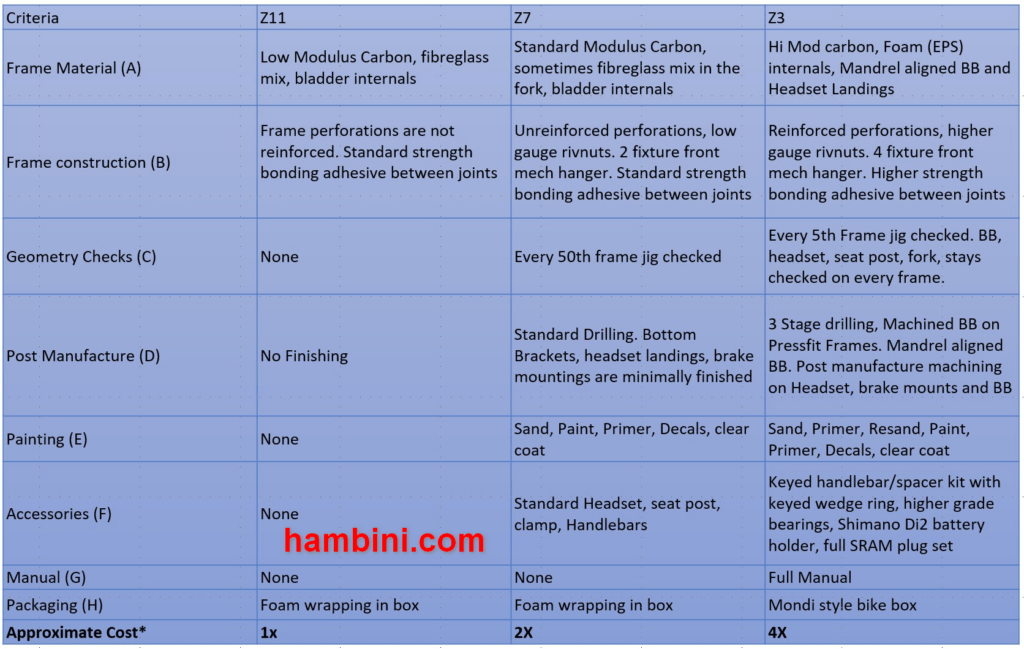

Lightcarbon’s quality assessment uses a detailed rating system, ranging from Z11 to Z3, with Z3 representing the highest quality. This system is further defined by criteria A to F, each addressing different aspects of the frames. For example, Criterion A focuses on frame material, where the quality can vary from standard Z11 to premium Z3. Similarly, Criterion C covers geometry checks, which also vary in precision depending on the assigned rating.

This structured approach highlights the complexities involved in frame manufacturing, where each characteristic is graded to meet specific standards. It emphasizes that the quality of Chinese-made frames is not solely defined by their origin but by the manufacturing oversight and standards applied. Understanding these ratings provides a clearer picture of what goes into each frame, helping consumers and brands make more informed decisions based on their performance needs and budget.

This system reveals that quality can vary widely within the same brand, making it crucial for buyers to look beyond basic descriptions and delve into the specific standards applied to each component. By understanding these detailed criteria, you can better navigate the diverse offerings within the cycling industry and select frames that align with your requirements.

I have summarized this in the table below

| Criteria | Z11 | Z7 | Z3 |

|---|---|---|---|

| Frame Material (A) | Low Modulus Carbon, fibreglass mix, bladder internals | Standard Modulus Carbon, sometimes fibreglass mix in the fork, bladder internals | Hi Mod carbon, Foam (EPS) internals, Mandrel aligned BB and Headset Landings |

| Frame construction (B) | Frame perforations are not reinforced. Standard strength bonding adhesive between joints | Unreinforced perforations, low gauge rivnuts. 2 fixture front mech hanger. Standard strength bonding adhesive between joints | Reinforced perforations, higher gauge rivnuts. 4 fixture front mech hanger. Higher strength bonding adhesive between joints |

| Geometry Checks (C) | None | Every 50th frame jig checked | Every 5th Frame jig checked. BB, headset, seat post, fork, stays checked on every frame. |

| Post Manufacture (D) | No Finishing | Standard Drilling. Bottom Brackets, headset landings, brake mountings are minimally finished | 3 Stage drilling, Machined BB on Pressfit Frames. Mandrel aligned BB. Post manufacture machining on Headset, brake mounts and BB |

| Painting (E) | None | Sand, Paint, Primer, Decals, clear coat | Sand, Primer, Resand, Paint, Primer, Decals, clear coat |

| Accessories (F) | None | Standard Headset, seat post, clamp, Handlebars | Keyed handlebar/spacer kit with keyed wedge ring, higher grade bearings, Shimano Di2 battery holder, full SRAM plug set |

| Manual (G) | None | None | Full Manual |

| Packaging (H) | Foam wrapping in box | Foam wrapping in box | Mondi style bike box |

| Approximate Cost* | 1x | 2X | 4X |

Also Available as a JPEG

I am old enough to remember when in the 50’s and 60’s Japanese goods, especially electronics, were thought of as cheap, useless crap. Then Japan started building quality products, especially motorbikes and automobiles, and who in the hollowed out factories of Detroit is laughing now?

I suspect the same will happen/is happening with Chinese bike parts. Early companies built poor frames and group sets, and the entire Chinese bike industry got a bad reputation. But now other companies are stepping up with higher quality. I be that some of these now surpass the quality of the Taiwan-built OEM carbon frames from all the major manufacturers.

So if I were in the market for a new bike, I would happily consider a Chinese made frame and component group set. I think that Shimano, Sram, and all the OEM brands may be in for a rude awakening in the next few years.