Pressfit vs Threaded Bottom Brackets

There are various camps out there on the internet that swear by threaded bottom brackets as a means to avoid creaking. This video below shows the pro’s and con’s of both.

There are various camps out there on the internet that swear by threaded bottom brackets as a means to avoid creaking. This video below shows the pro’s and con’s of both.

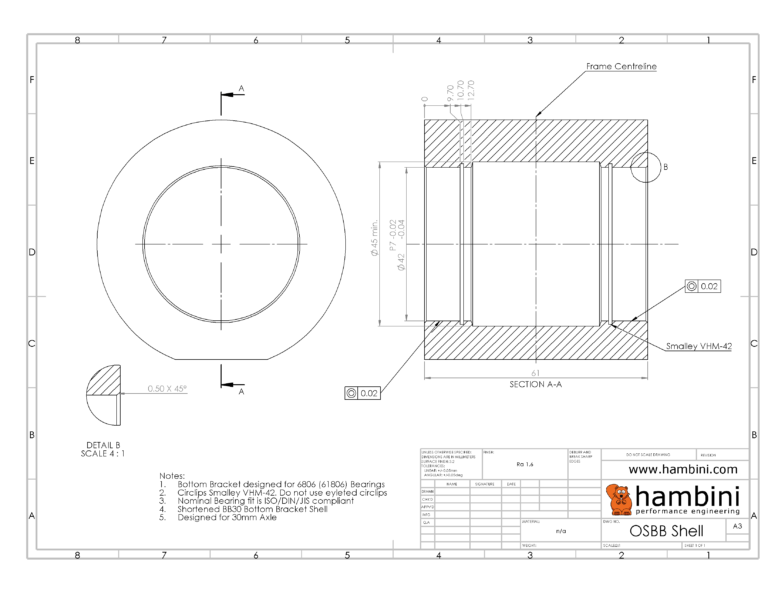

Introduction A question that crops up frequently is with regards to Specialized’s OSBB bottom bracket and what size it is exactly. The short answer is OSBB comes in 3 variants which are all called OSBB. 46×61, 42×68 and 46×73. A summary table is below, with the detailed drawings below that. Variant (Diameter x Width) (mm)…

This post provided aerodynamic performance data for wheels using disc brakes.

Right then, pull up a pew and prepare to be utterly dazzled. I was recently blessed with the arrival of a Wilier Triestina frame, a true masterpiece of modern engineering, sent in by some lucky chap whose bottom bracket was merely “experiencing a minor hiccup.” Yes, in the same way that a torrential downpour in…

Campagnolo cranksets have a reputation of being well engineered and robust but they are not without their problems and quirks. This post explains one of those in detail which surrounds the myths of the preload system, the “safety clip”, the system stiffness (or lack of it) and the involved nature of a bearing replacement. Campagnolo Ultra Torque is found on many of the upper range of Cranksets including the Super Record and Record.

One of my viewers sent in a set of Look Keo Blade pedals for a Hambini style teardown. Thanks to Paul of Shimano reaming fame for these. Pedals might often be overlooked in the grand scheme of cycling components, but for dedicated cyclists, their importance is undeniable. The Look Keo Blade pedals have earned a…

A concerned viewer recently reached out to the Hambini YouTube channel, reporting a peculiar failure of a Favero pedal axle. While Favero is widely respected for the precision of their power meters, there’s scant discussion about the quality of their mechanical engineering. In the “Unfortunate F*cker of the Week” segment, featured in Hambini’s Sunday reaming,…

No products in the cart.