9Velo Wheels CD58/65 WIDE: The Mechanical and Aerodynamic Benchmark

Introduction

9 Velo was not a mainstream brand. They avoided heavy advertising campaigns, influencer sponsorships and exaggerated product claims. Graphics were minimal and presentation was low key. Despite this understated approach, they were the most popular brand among Hambini Patreon members, supported by multiple genuine rider reviews over a long period. When they last appeared on the channel, the hubs were described as best in class and the wheels were found to be mechanically faultless. The latest version updated the previous CD series with a wider rim profile to suit the trend for wider tyres in road cycling. This revision followed the current move in the industry towards matching tyre profiles with wider rims for improved stability and reduced rolling resistance.

Box and Packaging

Delivery from China to the UK took 16 days from order placement to arrival. No import duties were charged in this instance, although that could vary depending on customs handling. The wheels arrived in a plain, unbranded cardboard box. Inside, they were secured with adequate protective packaging to prevent damage during transit. There were no cosmetic marks or shipping-related issues, indicating that the packaging design was sufficient for international transport.

Rim

The rims were carbon with local reinforcement at the spoke holes. This reinforcement was limited to the drill pad areas rather than being applied across the full rim width, which kept weight down without compromising structural strength where it was required. External width measured 30 mm and internal width 24 mm. The test set consisted of a 58 mm front and a 65 mm rear rim depth. Wider rims were generally less affected by crosswinds because the pressure differential was reduced, and deeper profiles could be beneficial for aerodynamic efficiency in suitable conditions.

Internal rim surfaces were clean, with no excess resin build-up and no visible voids on visual inspection. The finish indicated good manufacturing quality without the need for cosmetic fillers. The rims were hooked, making them compatible with clincher and tubeless tyres. Tubeless compatibility provided flexibility for riders who preferred lower pressures for comfort or rolling resistance benefits.

Spokes and Nipples

Both sides of the front and rear wheels were cross laced. This increased torsional stiffness and improved power transfer under sprinting, climbing and other high torque conditions. Load distribution from this pattern reduced stress concentrations in both the hub and rim, improving durability over long-term use. Lateral deflection under load was reduced, helping the wheel maintain true for longer periods between servicing.

Spoke tension was measured to be uniform across each wheel. Variations in spoke thickness could cause inaccurate readings with some spoke tension tools, so 9 Velo measured spoke thickness during assembly and selected spokes with minimal variation. The final tensioning was carried out using ultrasonic equipment, ensuring consistent and repeatable results.

The wheels used aero-profiled bladed spokes. These reduced aerodynamic drag compared to round spokes by presenting a narrower profile to airflow. They also increased stiffness under load. The spoke nipples were semi-exposed, reducing aerodynamic disturbance while allowing direct access for adjustments without tyre or rim tape removal. This simplified truing and maintenance without compromising performance.

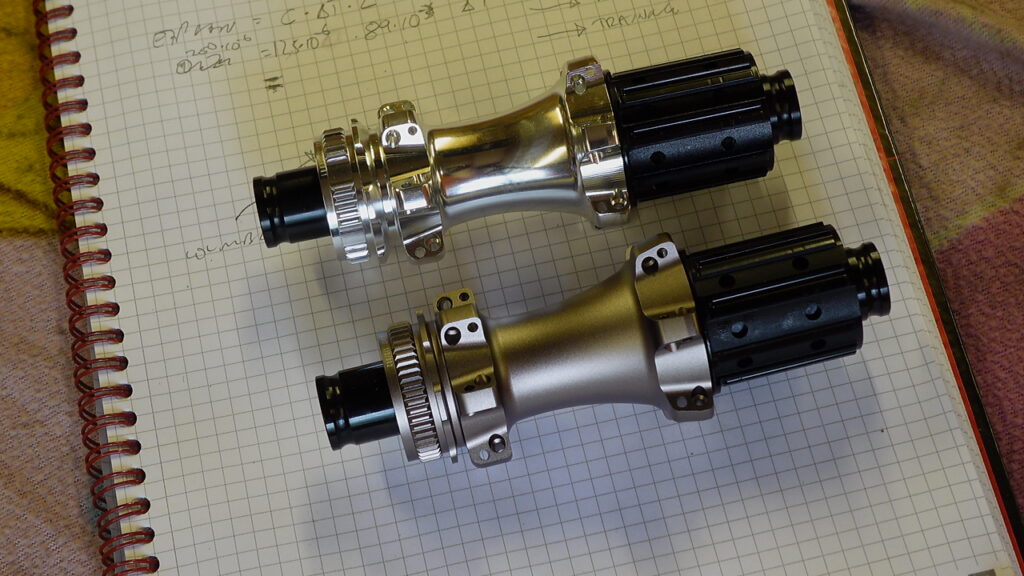

Best in Class Hub System

The hubs were manufactured to tight tolerances, producing almost zero radial and lateral runout. This precision resulted in smooth rotation and extended bearing life. Vibration levels measured at the hub interface were low, supporting efficient power transfer. The test wheels used titanium freehub bodies, with aluminium 7075 as the standard option. Engagement was fast and secure, which was beneficial for high torque riding such as sprinting or climbing out of the saddle.

Mass distribution and rim stiffness gave the wheels a high critical speed, resisting harmonic oscillation that could cause instability. Bearing seats were machined to tight tolerances, ensuring proper fit and alignment of the bearings. This avoided the misalignment and poor fit that were common causes of increased vibration and noise in other wheelsets.

Vibration analysis showed low ball spin frequency, fundamental train frequency and ball pass frequencies on both inner and outer races. These values indicated minimal internal stress and good rotational precision, both of which contributed to efficiency and extended bearing life. Accurate bearing fits reduced micro movement between components, preventing fretting corrosion and wear on bearing seats. Bearings ran under near ideal conditions with low resistance. Combined with extremely low runout and precise freehub machining (9Velo claim 0.003mm accuracy, my measuring devices have a practical accuracy of 0.010mm), drivetrain energy loss was minimised, giving faster pick up, smooth engagement and low rolling drag.

Mechanical Perfection

From the box, the wheels were balanced to a high standard and manufactured to tight tolerances. This gave them strong resistance to speed wobble even at high speeds. High critical speed also reduced transmitted road noise, allowing the use of higher tyre pressures without sacrificing stability. Higher pressures could lower rolling resistance, which was advantageous in time trials and on smooth racing surfaces.

Most wheelsets had a first critical speed around 37 km/h, meaning riders could encounter instability at moderate race speeds. These wheels measured above 50 km/h for critical speed, making them stable in descents, high-speed corners and sprint finishes. The combination of precision balance and structural stiffness reduced the need for rider corrections at speed.

Aerodynamics

Wind tunnel testing showed above average aerodynamics for the rim depth. The use of wide aero spokes and minimal nipple exposure contributed to reduced drag.

The rim to tyre transition is amongst the best available on the market. The transition is a known to produce turbulence and the 9Velo wheels manage this issue well.

The cross lacing pattern introduced a small aerodynamic penalty compared to radial lacing on one side, but this was within the margin of error for testing and outweighed by the mechanical advantages.

In transient wind conditions replicating real-world riding, the wheels maintained stability. Pressure distribution between windward and leeward sides remained balanced, and load release was controlled. Only very strong wind conditions were likely to push the wheelset beyond the control range of an experienced rider.

Racing Experience

Over a year of use in time trials, duathlons and high intensity training, the wheels retained their structural integrity. There was no measurable loss of true, no spoke tension relaxation and no signs of delamination or micro cracking in the carbon layup. Torsional and lateral stiffness remained high with little flex under load. Aerodynamic performance reduced system drag, and heavy braking or accelerations did not cause any degradation in bearing performance or rim stability.

Spares and Service

Spares availability was not an issue. The wheels used standard bearings, an H-works hub and standard carbon spokes. These were available from multiple UK suppliers, and availability in continental Europe, Australia and North America was expected to be similar.

Summary

9 Velo wheels were built with mechanical quality as the primary focus. Cross lacing on both sides of both wheels, consistent spoke tension, carbon rims with local reinforcement, precision-machined hubs and accurate bearing fits resulted in high stability, low vibration and strong durability. High critical speed, above average aerodynamics and easy access to spares made them stable, efficient and straightforward to maintain over the long term.

This is a polished and highly competent wheelset. For 95% of riders, it will meet every requirement with ease. It is clear why it comes so highly recommended by those who know what matters. The absence of marketing hype and the understated ability to deliver one of the best-performing wheelsets available speaks volumes.

Photographs

Watch on YouTube

Detailed Results

A full detailed technical analysis with weights, fits and vibration data is available on the Hambini Patreon Channel

Discount Code

The discount code hambini10 will get you 10% off at 9Velo

Hello sir,

Can you help me please.

Were can I find your datapoints from windtunnel testing for this wheelset and the one(s) that you compared to?

And used protocol would be really amazing!

Kind regards from Holland,

Frank

They are available on patreon.