Hambini PF30 Bottom Bracket Shimano Crankset

£155.00 Ex. VAT

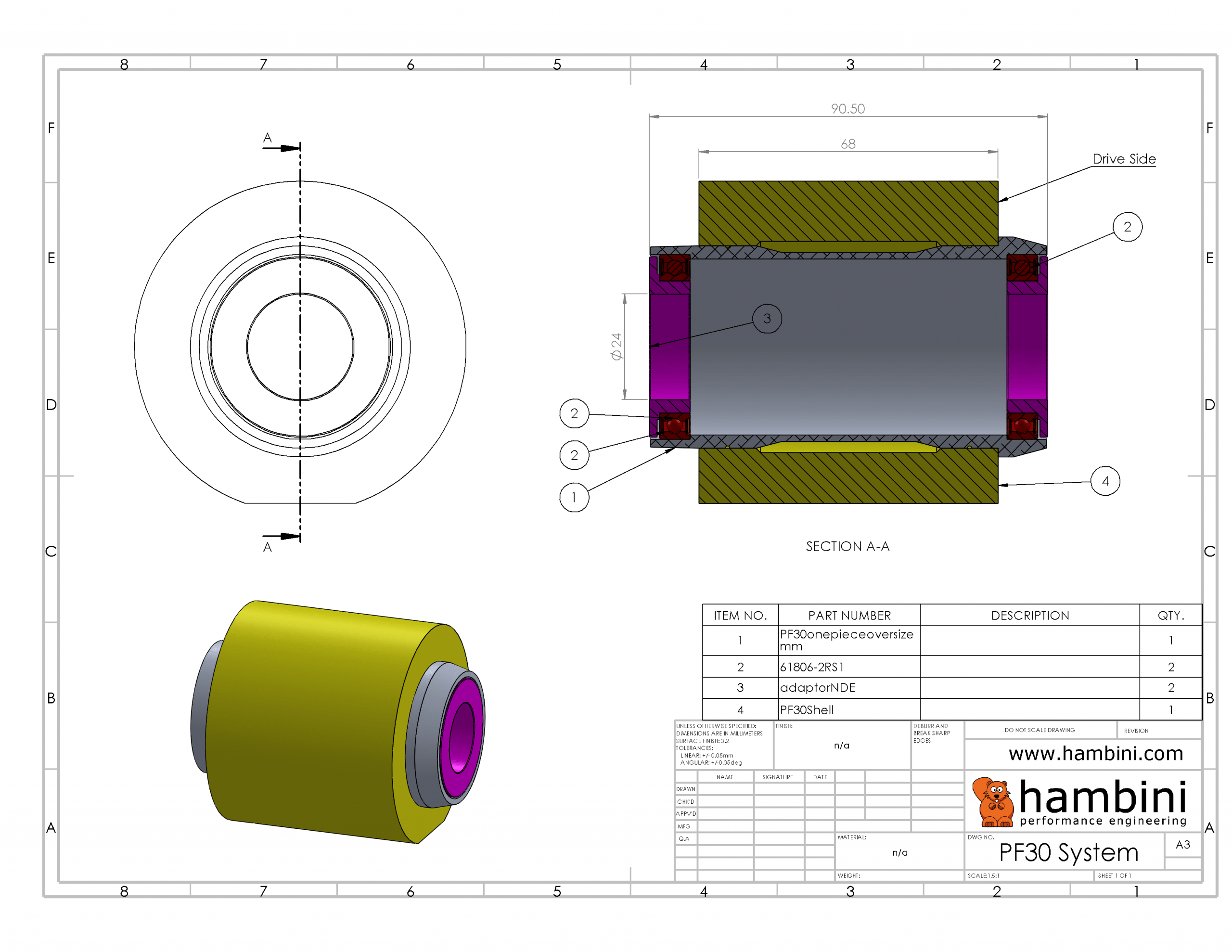

This bottom bracket is designed to interface a Shimano 24mm Hollowtech 2 Crankset (Sora, Tiagra, 105, Ultegra, Dura Ace) and Shimano Compatible (Some ROTOR and FSA) 24mm Cranksets with a bike frame that uses a PF30 Bottom Bracket (46mm Nominal Inside Diameter x 68mm wide).

Out of stock

Description

This bottom bracket is designed to interface a Shimano 24mm Hollowtech 2 Crankset (Sora, Tiagra, 105, Ultegra, Dura Ace) and Shimano Compatible (Some ROTOR and FSA) 24mm Cranksets with a bike frame that uses a PF30 Bottom Bracket (46mm Nominal Inside Diameter x 68mm wide).

Hambini Bottom Bracket Overview

- Aerospace Tolerances for a no slop fit

- One Piece design aligns the bearings perfectly, reducing the likelihood of creak

- Fitted with NTN/NSK/SKF/FAG/Koyo Bearings

- No Hammers are required to install or Remove the Bottom Bracket

- Fully Serviceable, the bearings can be replaced quickly and easily

- It is supplied with fitting adaptors in M12 (or 1/2 inch), a press or studbar will be required to facilitate installation

- One year warranty on the bottom bracket body

Precision Engineered and Manufactured in the United Kingdom

Hambini Bottom Brackets are amongst the lowest friction bottom brackets in the world. They are used by recreational cyclists, road racers, triathletes and time trialists from around the globe. They are of proven design and are manufactured in the United Kingdom. These units are of a one piece construction which makes them inherently resistant to creak, they will maintain perfect bearing alignment and function under loads in excess of 4000W.

Hassle-Free Maintenance

All Hambini bottom brackets can be installed and removed with a conventional bearing press, they use a controlled method of installation using the recommended fitting adaptors, they require no hammers or specialized tooling for removal. Additionally, the wearing component – the bearings – can be serviced in situ or removed within just a few minutes. The bottom bracket has been designed to be fully rebuildable.

Unrivalled Performance

Unloaded bearing spin tests are a poor measure of frictional performance but they do highlight good bearing alignment. The link below is to a video of a Hambini Racing Bottom Bracket that had completed 10,000km

Class Leading Parasitic Drag Loss (Friction)

The graph below shows how Hambini bottom brackets perform in comparison to the bottom brackets of other manufacturers. The test conditions model real world cycling and more importantly mimics realistic frame tolerances. All of these tests have been conducted with an eccentricity of 0.1mm which is generally the maximum permitted in frame specifications – the reality is tolerances have been known to be much worse than this. Misalignment is more critical to friction than the type of bearing ball material, a slight misalignment can easily outweigh the difference between a top of the range NTN bearing and a mediocre ebay no name bearing. The results show that bottom brackets which have an element of structural linkage between the drive and non-drive sides (one piece/threaded etc) perform much better than those which are multi piece.

The high torque and low RPM of pedaling causes high Hertzian contact stresses on bearing surfaces which cause friction levels to change over time. Those bottom brackets which have used ceramic bearings, start off with fairly low levels of friction but over time their friction increases dramatically. The super hard ceramic balls grind a track into the comparatively soft bearing races causing friction to increase. This would be analogous to trying to drive a locomotive train on a road, the wheels would cut grooves into the road surface due to the huge difference in surface hardness.

Bottom Bracket Stiffness

A Hambini BB is a one piece bottom bracket. It actively contributes to the stiffness of the bike’s pedaling platform. Threaded and multi piece bottom brackets have an element of play in their design so they do not contribute anywhere near a comparative level of stiffness. Reviewers of Hambini BB’s often comment on their feeling of improved stiffness, this is due to them being one piece and undergoing a proprietary heat treatment process. This makes them stronger and stiffer. This is a difference the end user cannot see – but they can feel.

Support

A lot of support questions can be answered by visiting the support section.

Popular support topics:

- Installation of a Pressfit Hambini Bottom Bracket

- Servicing of a Hambini Bottom Bracket (Bearing Service)

- Removal of a Hambini Bottom Bracket

Still need some help?

You can contact support on support@hambini.com or use the Contact Form

Mket –

Hideously expensive but miles better than anything else out there. I tried them all, Enduro, Wheels MFG, Praxis. Not a patch on this one.

MikeD –

Items came in a recycled brown box. Once opened, you can see this is a quality product. It really does soon like butter. The gaps between the dust shields are tiny but they don’t rub. Installation in my cannondale frame was straightforward and riding afterwards has been a pleasure. Excellent product.

Asmin James –

Very well made and super stiff. bearings are like butter. Thoroughly well engineered and technical support to match.

Barry Grayson, Cleveland OH –

The delivery was super quick. 5 days from ordering to my mailbox with the standard service. I had a few questions and these were answered quickly. The bottom bracket is crazy. I have never seen machining like this, The NTN bearings are very good. First class. I would recommend. Good YT channel too. Thankyou Hambini

Jesper S –

I don’t know why i wasted my time with multiple rotor and token bottom brackets. This is miles better. Installation took me about 10 minutes, it comes with the bearings installed and i just pressed the entire cartridge in. Technical support is very good. Every question answered, often in minutes.

Maxgh1978 –

5 stars from me. Cured all of my problems and crank spins so freely

Cameron Brady, Billings MT –

Great looking product and functions well. Very high machining quality.

Simon Owen –

Lovely… Just lovely… creak free happiness. I had wasted my time with Wheels MFG adpators, ceramicspeed and Token. This beats them all hands down.

dathers –

Fantastic piece of engineering, a little bit expensive, hence only 4 stars for value, however I suspect overtime this bracket will prove to be an excellent purchase

rirwin –

Easy to install and is beautifully machined! Took it out for a short spin and everything felt a little stiffer as I pedaled.

dazmug –

Easy to install. Very satisfied.

Ken Close –

I recently got back into bike racing, having been away for a while. Along with a few new trends I was greeted by the unpleasant surprise of push fit bottom brackets. I was going through bottom brackets like they were going out of fashion before I got this one. Well designed, well machined, it is beautiful.

oshkosh –

After bottom bracket issues on my Cervelo R3, I found Hambini performance engineering. After watching the you tube videos of the one piece bottom bracket made by Hambini, who also rides a Cervelo,I knew this would sort out my creaking issues. I ordered a complete bottom bracket. I received an invoice and was pleasantly surprised that all fitting/removal parts were included. Delivery to South Africa took a while but received everything intact. Installed product 7/3/2017 and have ridden 280 km since without a problem.

Miranda Forster –

Couldn’t ask for more, Everything was perfect.

MegaEXOMan –

Good BB, very slick service, easy install.

Harvey866 –

The quality of this cannot be faulted. First class engineering, works well and is a joy to ride. However all of this comes at a price and I’m not sure it is worth it. The service here is good. It’s one of the advantages to dealing with a technical guy.

Velluthulai –

I bought my cannondale from Sigma cycles in London with the bike 2 work scheme and had no end of problems with it. Sigma didn’t really have a shit by the end and I was left scratching my head. My work colleague recommended Hambini as his son is an Engineer that works with him at Airbus. I contacted him, he sent me the bottom bracket and due to my apprehension a press so I could install it. It was very easy and straightforward to do. I was so impressed with the press, I bought that as well. Hambini’s attention to detail and customer service are both excellent. You pay a slight premium for a Hambini BB but it spins like no other and has service levels to match.

Rivdae –

Ordered on Saturday, arrived at my house in LA on Friday. I fitted it over the weekend and wow! This has been made by someone at the top of his game. Rides well, full gas no creaks, feels way more rigid than before. My only regret is not buying one for my other bike to save shipping.

Pete Olgenssen Miami FL –

Normally, I don’t leave reviews but this experience is worthy of an exception. The purchasing experience was truly fantastic. I asked a few questions around fitting and I was provided with drawings and sketches to see if it would fit. Once this was out of the way, the BB arrived in FL 7 days later. I stupidly fitted it incorrectly by leaving the delrin piece in when pushing it in. Make sure you don’t do that. I contacted Hambini, he sent me a replacement bearing and tool to swap them out free of charge. Despite being in the US, it was sent UPS express so I wasn’t without the bike. I can’t thank him enough.

Cyril Canvaroue –

I previously used 2 sets of plastic adaptors and they always ended up coming out about 2 mm on each side of the bottom bracket shell after a few rides. Also the bearings would not last .

So after watching a few hambini videos I decided to buy that metal masterpiece.

It was very easy to fit following his video instructions.

It looks neat and precise. Also feels stiffer than the plastic crap I had before.

I Nyoman Naya –

Appreciate provided close communication on the product selection and what is coming with it. Installation is a snap and performance is instantly recognized. The machining is top quality and it is obvious that QC was performed closely to the allowed tolerance.

My suggestion is to provide more economical shipping alternative to Jakarta Indonesia… Thanks.

richard karmann –

fantastic bottom bracket which is super smooth with creak free stiffness . a quick delivery, which was also easy to install following Hambini’s video.

OG –

You want a real engineering? I surely appreciate such. A year ago I have bought the PF30 to Shimano Classic Bottom Bracket so you may well take my comment as a small review. The BB has seen Summer, Winter, salt, rain, grime, dirt, abuse, removal, installation, bearings replacement, and still runs smooth as day 1. Ok, it might be “just a shell”, yeah, well at least that “shell” does it’s purpose very good. My experience working with bikes for over 25 years, allows me to humbly share my opinion that Hambini’s BBs are the best, at least for shimano. I can also compare it to other manufacturers, one being BBInfinite, again PF30, which does the job good but they are simply not on the level of Hambini.

Another very important thing, Hambini does care for the small guy as well, obvious from his patience to reply/answer, explain, give advice and support when needed!

Thank you sir!

Rafal Lapszewicz –

Thank you hambini for all your help.

Terence Bailey –

This is a quality product!!!

Had problems with BB hole being under size, Hambini sent a video link that showed how to rectify the problem.

What this guy does not know isn’t worth knowing!!!

e –

Scott in Pennsylvania, USA –

I’ve been running the Hambini PF30 to Shimano BB on my Bianchi Infinito since 2017. It is flawless! The design is great. No creaks. Super stiff and smooth. I ride the bike in the rain, no issues at all. After 5 years of riding the bearings are still so smooth that if I lift the rear wheel and spin the cranks, the rear wheel keeps my cranks spinning! There is no friction in the bearings. Best BB available.