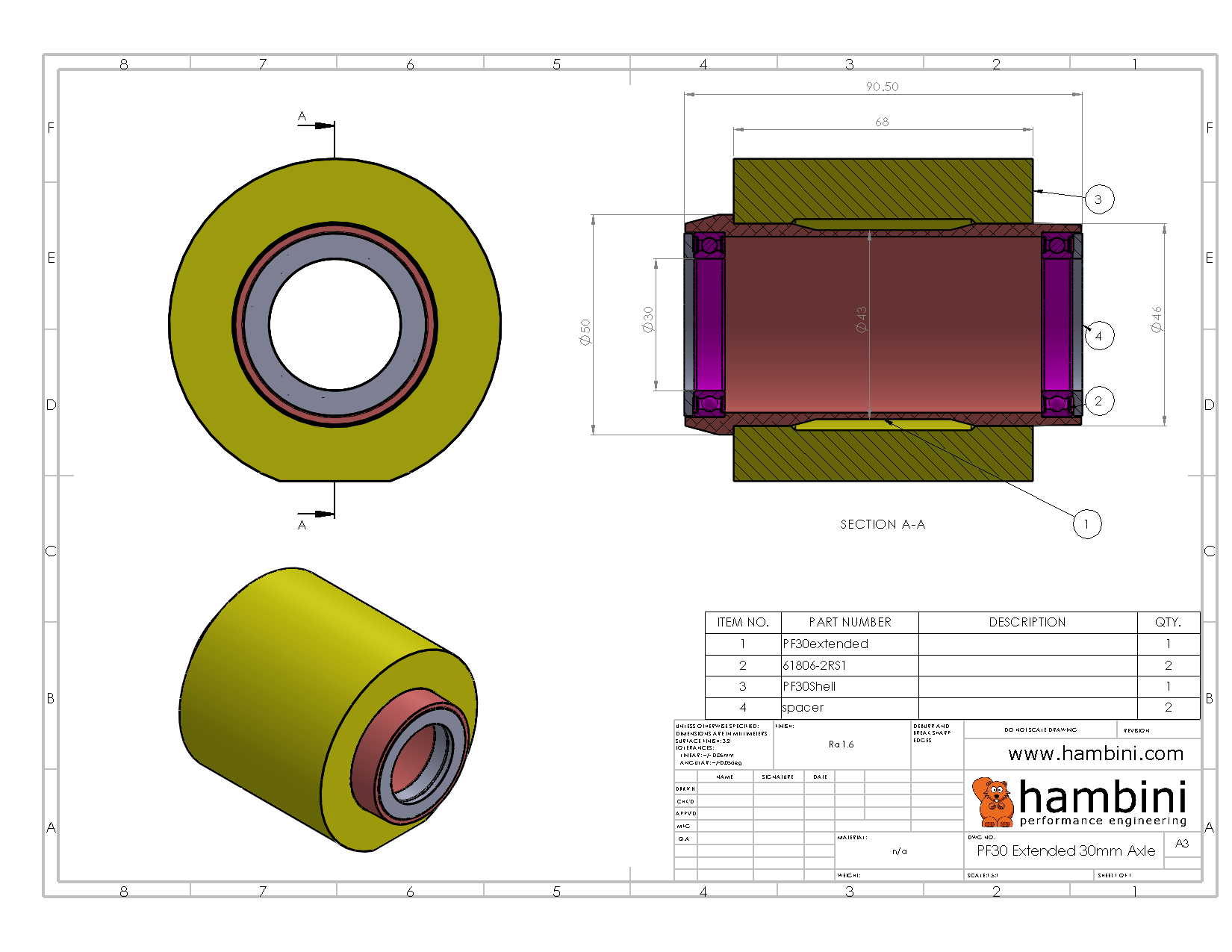

Hambini PF30 Bottom Bracket 30mm BB30 Long Axle Crankset

£155.00 Ex. VAT

This bottom bracket is designed to interface a 30mm Crankset (minimum 90.5mm DBCA) with a bike frame that uses a PF30 Bottom Bracket (46mm Nominal Inside Diameter x 68mm wide).

Out of stock

Description

This bottom bracket is designed to interface a 30mm Crankset (minimum 90.5mm DBCA) with a bike frame that uses a PF30 Bottom Bracket (46mm Nominal Inside Diameter x 68mm wide).

Hambini Bottom Bracket Overview

- Aerospace Tolerances for a no slop fit

- One Piece design aligns the bearings perfectly, reducing the likelihood of creak

- Fitted with NTN/NSK/SKF/FAG/Koyo Bearings

- No Hammers are required to install or Remove the Bottom Bracket

- Fully Serviceable, the bearings can be replaced quickly and easily

- It is supplied with fitting adaptors in M12 (or 1/2 inch), a press or studbar will be required to facilitate installation

- One year warranty on the bottom bracket body

Precision Engineered and Manufactured in the United Kingdom

Hambini Bottom Brackets are amongst the lowest friction bottom brackets in the world. They are used by recreational cyclists, road racers, triathletes and time trialists from around the globe. They are of proven design and are manufactured in the United Kingdom. These units are of a one piece construction which makes them inherently resistant to creak, they will maintain perfect bearing alignment and function under loads in excess of 4000W.

Hassle-Free Maintenance

All Hambini bottom brackets can be installed and removed with a conventional bearing press, they use a controlled method of installation using the recommended fitting adaptors, they require no hammers or specialized tooling for removal. Additionally, the wearing component – the bearings – can be serviced in situ or removed within just a few minutes. The bottom bracket has been designed to be fully rebuildable.

Unrivalled Performance

Unloaded bearing spin tests are a poor measure of frictional performance but they do highlight good bearing alignment. The link below is to a video of a Hambini Racing Bottom Bracket that had completed 10,000km

Class Leading Parasitic Drag Loss (Friction)

The graph below shows how Hambini bottom brackets perform in comparison to the bottom brackets of other manufacturers. The test conditions model real world cycling and more importantly mimics realistic frame tolerances. All of these tests have been conducted with an eccentricity of 0.1mm which is generally the maximum permitted in frame specifications – the reality is tolerances have been known to be much worse than this. Misalignment is more critical to friction than the type of bearing ball material, a slight misalignment can easily outweigh the difference between a top of the range NTN bearing and a mediocre ebay no name bearing. The results show that bottom brackets which have an element of structural linkage between the drive and non-drive sides (one piece/threaded etc) perform much better than those which are multi piece.

The high torque and low RPM of pedaling causes high Hertzian contact stresses on bearing surfaces which cause friction levels to change over time. Those bottom brackets which have used ceramic bearings, start off with fairly low levels of friction but over time their friction increases dramatically. The super hard ceramic balls grind a track into the comparatively soft bearing races causing friction to increase. This would be analogous to trying to drive a locomotive train on a road, the wheels would cut grooves into the road surface due to the huge difference in surface hardness.

Bottom Bracket Stiffness

A Hambini BB is a one piece bottom bracket. It actively contributes to the stiffness of the bike’s pedaling platform. Threaded and multi piece bottom brackets have an element of play in their design so they do not contribute anywhere near a comparative level of stiffness. Reviewers of Hambini BB’s often comment on their feeling of improved stiffness, this is due to them being one piece and undergoing a proprietary heat treatment process. This makes them stronger and stiffer. This is a difference the end user cannot see – but they can feel.

Support

A lot of support questions can be answered by visiting the support section.

Popular support topics:

- Installation of a Pressfit Hambini Bottom Bracket

- Servicing of a Hambini Bottom Bracket (Bearing Service)

- Removal of a Hambini Bottom Bracket

Still need some help?

You can contact support on support@hambini.com or use the Contact Form

Additional information

| Crankset Type | |

|---|---|

| Frame | |

| Manufacturer |

Jantu –

5000km in and no creaking, flexing or noise. Bearings still spin freely and are clearly good quality. I used to use ceramic bearings before, now i don’t bother Hambini customer support at every point was excellent. I would recommend you contact him before you buy anything. He will give you good guidance.

JTP –

The engineering in this BB is first class. Other BB manufacturers need to take note of the “no nonsense” approach to marketing. it’s refreshing to see someone who uses hard theory. Hambini response to questions is first class. Responses are received very quickly and detailed. When you buy this bottom bracket, the bit you are buying that is priceless is the expertise. It makes the local bike shop look like amateurs. The quality of this item is exceptional. The box it comes in is functional and I’d rather not pay an extra £5 for a nice box. Installation was as per the videos. Make sure you take the spacer out of the drive side!!!

Alan38 –

You won’t realise how poor your own bottom bracket is until you use a Hambini one. The difference is like night and day. Impeccably made, first class customer service throughout. I was a bit dubious about buying a bottom bracket from here because it is not a well known brand but frankly I cannot speak highly enough of him. He knows his product inside out, very helpful, very quick to respond. Is happy to customize where appropriate. Top job

KurtC –

This is very clever because the Hambini design moves the bearings very close to the crank arms which makes the BB feel stiff. It spins freely and does not creak. Hambini’s customer service is the best I have come across.

Matty –

Hambini was very helpful from the beginning, his responses always very quick. Quality of the product is superb. Would I go for it again? Absolutely!

Jonny Come Lately –

This was suggested to me by a few people over at weight weenies Service was phenomenal. I had some queries when installing it, these were resolved within the hour and that was at 10pm at night! Out riding the difference is massive. The bike feels much stiffer, I thought the bike was stiff in the BB area before but after installing this, it’s a new level. I cried at the thought of spending $220 on a bottom bracket and wasn’t sure if buying one from the UK was a good idea. But I don’t regret buying this. It’s changed my riding from trying to adjust my pedal style to avoid creaking to going for it hell for leather. I wish I had discovered it sooner.

Steve Jones –

Customer Service is extremely good, speedy responses and accurate technical information. Final product is stunning. It functions as well as it looks. It is expensive but ride on it and you won’t go back.

Bryan H –

I cannot fault this item for quality, fit and finish. All of my creaking has gone and the pedalling quality is stiffer. Only gripe is it’s expensive.

Jordan Schumer –

It’s expensive but very well made. Comes in a crappy box but it is well packed. Fitting was easy and done in 15 minutes. I recommend watching the video beforehand. On the bike it’s faultless.

Matt Rixon –

Similar to the BBinfiite design but costs two thirds less. Well made, machining quality is excellent and the bearings spin very freely. Clearly not a mass produced product. Very fast delivery. It’s not clear in the description, this comes with everything you need to install it apart from the press

Jim Dale, Billings MT –

Hambini has made a world of difference to my riding. This bottom bracket is superb. Technical support was excellent and the item is beautiful. I love it. My only mistake was not buying it sooner.

Hakim339 –

No shiny box, no marketing, not even a manual… But I’d buy another one in a flash. Customer support is very good here, this bottom bracket is also very good. My LBS fitted it and the guy almost jizzed himself asking where it came from. The bike feels completely different now. I did a back to back test on two cannondales, mine with a hambini and another with wheels mfg. There is no contest. Hambini wins hands down. Very impressed, I just wish it was cheaper.

Blairha73 –

No creaking. No flexing, easy to install. Best £75 I spent on my bike. Well engineered, quality product but don’t expect flash packaging.

SeatonRacer –

I wanted to buy the black one but it was out of stock, so I plumped for this. I’m very happy with the purchase, it looks really nice in the flesh. Stiff, well made. delight to touch.. It’s expensive though.

Jimmy Casiraghi, NY –

I have not had much experience with suppliers from Europe. Hambini customer service is excellent. Attention to details and speed of response are out of this world. I would certainly recommend this company and would have no hesitation in buying again. The bottom bracket is bordering on art work.

Ulf Hansen –