Hambini Titanium Racing BSA Bottom Bracket SRAM DUB

£447.00 Ex. VAT

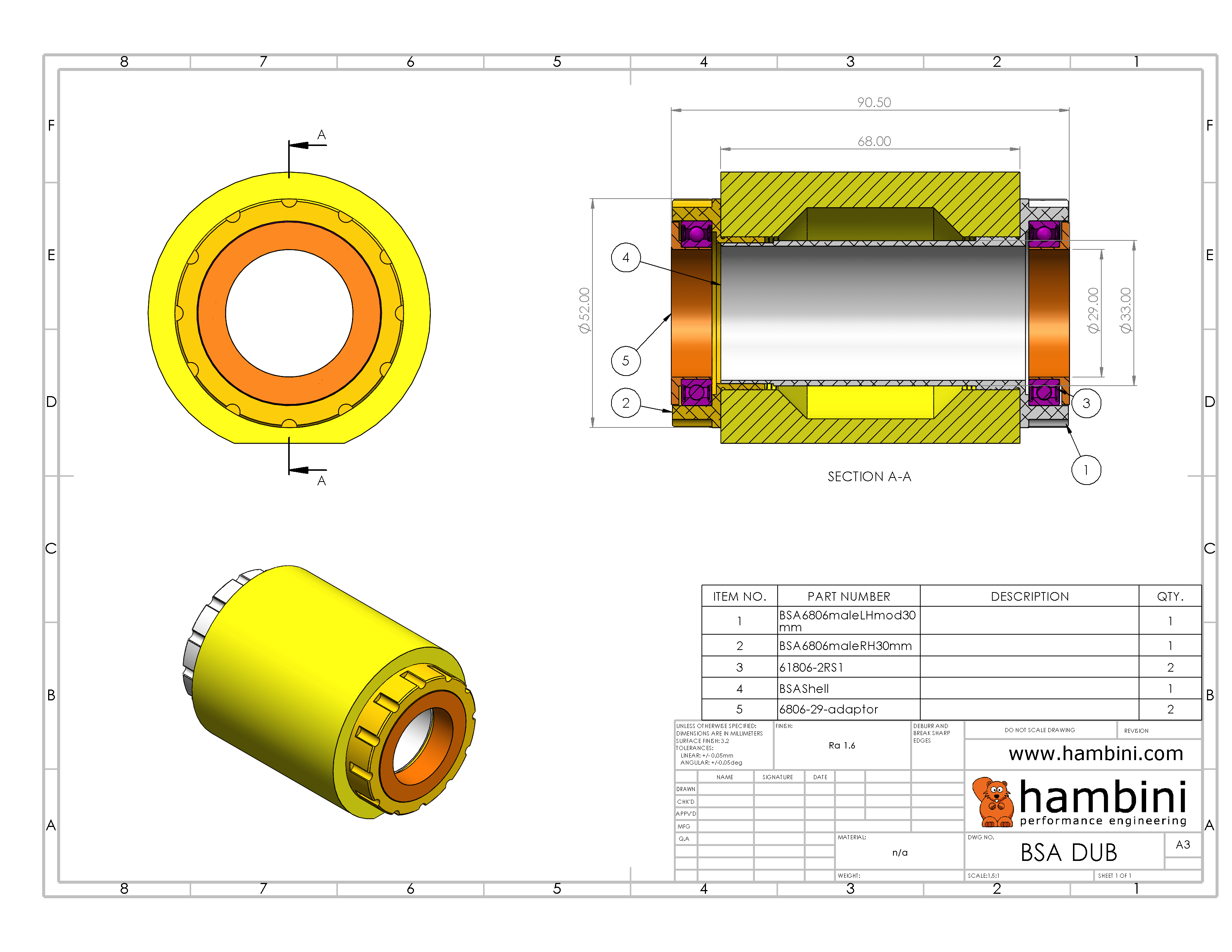

This bottom bracket is designed to interface a SRAM DUB Crankset with a bike frame that uses a BSA Bottom Bracket. It is made of Titanium

2 in stock

Description

- Made from Titanium

- BSA 68mm Threaded (1.37 x 24TPI), Often referred to as English, BSC or ISO threading.

- The drive side has a Left Handed Thread, Non Drive Side has a Right Handed Thread

- 29mm (28.99) DUB compatible

- The drive and non-drive sides are aligned via an internal male/female sleeve

- Top of the range 6806 SKF/NTN/FAG/NSK bearings fitted as standard

- Non contacting Seals

- It is extremely important that any frame this BB is fitted to has a flat face (0.02mm) that is perpendicular to the threads. Diameter of 52mm

- Tightening Torque of 8Nm (BSA Bottom brackets will self-tighten)

- Fitting instructions are here,

- The fitting tool to install this is available here

This bottom bracket features the largest bearings of any commercially available unit for DUB axles. They are standard 6806 bearings which have a load rating that is significantly higher than the 4029 bearings used by other manufacturers.

Please be aware that DUB Axles vary in DBCA and you may need additional spacers. Please read the guidance on this here

Contemporary frames from the likes of Specialized and Cannondale use threaded BSA bottom brackets. This Hambini Ti bottom bracket was designed to address a growing trend of fitting large-format axles (SRAM AXS/DUB and 30mm) into BSA shells. Large-format axles result in thin sidewalls in the threaded regions which cause undesirable bending and twisting. The reduction in cross-sectional area is offset in Hambini Ti Bottom brackets with the use of Titanium which is substantially stronger and stiffer than the aluminium alloys used by other manufacturers.

5 reviews for Hambini Titanium Racing BSA Bottom Bracket SRAM DUB

Q & A

NTN 6806 LLU CN would be the suggested choice.

Kevvo –

I bought myself a new Specialized Tarmac, this now comes with a threaded shell. My last one had a BB30 OSBB. I had a Hambini BB in that one and could not have been happier.

I bought this without thinking twice, all of those moaners on internet forums have obviously not tried Hambini BB’s. Yes it is expensive but you’ll quickly forget about that when you have hassle free, silent, drag free cycling. First class finish, technical support and a quality product.

The fitting was perfect, the cranks spin forever. The OE sram BB looks like a cheap knock off compared to this.

mark m. –

Quality BB, no plastic here, precision machined titanium, easy install be mindful of the low torque required 8Nm, the install tool is also quality my LBS was impressed with both the BB and tool , great communication with Hambini regarding my questions, Definitely recommend

Huang Teng Tan –

The absolute pinnacle in bicycle engineering.

The tolerance of the Titanium BB is even higher than the Aluminum version as it is not anodised. It is obvious when the male and female centre bits come together as the fit is snug (zero play).

When installed on my Tarmac SL7, the crank spin is absolutely smooth and only comes to a stop after 30 plus seconds.

Seeta T. –

Excellent product…

Kenmore J –

This has replaced a Wheels MFG bottom bracket which lasted about a month.

Fitting the Hambini BB was straightforward. From the outset, the difference is significant. There is no flex, there is no noise and above all you forget it is there.

The service, from pre-sales to receiving it and post-sales technical queries, has been exemplary. As others have said, Hambini is a completely different beast in a professional capacity. He is clearly a very capable engineer and at the top of his game. It is a world-class product with world-class service. It was expensive, but as they say, you get what you pay for.