Hambini Bottom Brackets get roasted: Bottom Bracket Review and Quality Control

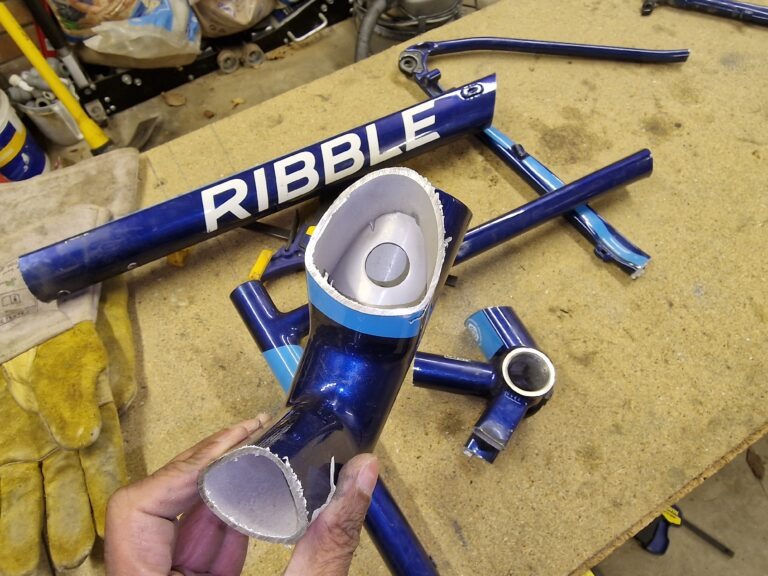

This video uploaded by youtuber Peak Torque shows a Hambini BB having it’s engineering tolerances judged. Some key points

- It’s a BB86 Shimano Racing Edition Bottom Bracket

- The bottom bracket tolerances are accurate to 0.005mm, that is less than the diameter of a human sperm cell.

- The eccentricity was found to be 0.010mm (0.0005inch), and the recommended tolerance was 0.1mm. It was therefore 10 times more accurate than the specification allows.

How is .01mm 100x better than .1mm

it’s a tighter tolerance, it’s therefore more accurate

Not necessarily 100x better but with tighter tolerances there is more rigidity, less wear and tear. In engineering 0.1mm or 0.004” is quite a large tolerance and with current DNC or CNC Machines tolerances of 0.05mm are quite easily achieved with aluminium components of batches of 200 off or more just as easily as with components of greater tolerance. Paying £4K for a bicycle I’d only expect the best from the very few machined components included.

Surely this should read ten times better not 100 times.

The eccentricity was found to be 0.010mm (0.0005inch), the recommended tolerance was 0.1mm. It was therefore 100 times more accurate than the specification allows.

5 year old Mathematics

Fixed it. Thanks for pointing it out