Testing to Find the Fastest Bicycle Wheel Hubs

The aerodynamic performance of wheels often grabs the headlines and the marketing budget but the reality is the hubs and the bearings within them will have more of a performance differential for the average cyclist. As an example, the power differential between wheels of an equivalent depth at speeds of less than 35km/h will only be 1-2W, the difference in bearing friction can easily exceed that.

Wheel hubs and freehubs account for around 60% of the rotational friction in a bicycle drivetrain. The remaining friction is from the pedal bearings, bottom bracket and pulley wheels. The total amount of friction is small but a cost effective marginal gain.

The term rotational drag has been used of late to describe the amount of power required to spin a wheel up to speed. This loss is a significant aerodynamic loss of about 25 to 30 percent. Rotational drag is not the same as frictional drag which comes from the mechanical components.

Wheel Hub Design methodology

There are a several engineering considerations to be made when designing hubs which have been discussed below

- The most obvious is the choice of bearing type. The vast majority of hubs use 6000 series ball bearings which are deep groove. A notable exception are Shimano and some Campagnolo/Fulcrum wheels which use cup and cone bearings. A cup and cone bearing is a type of angular contact bearing. A cup and cone bearing will always have more friction than a radial bearing because of an axially oriented contact angle. A loose cup and cone bearing allows for fairly slack manufacturing tolerances.

- The bearing material (ceramic or steel) is often credited with lowering the friction in a hubset. The reality is the seal and choice of grease will have more effect.

- The axle size determines the friction torque from the bearings. Axle sizes of between 10mm and 17mm are common on bicycle hubs. The smaller axles will always have lower frictional torque because the moment lever is shorter, the negative effects are the wheel hub will have more flex and the bearings will not last as long.

- Machining accuracy, a lot of hubs are manufactured in Taiwan by forging aluminium 7075 alloy and then machining bearing landings afterwards. This is a standard process but it can be riddled with quality control issues. Having bearings that are misaligned due to slack jigs and holes that are too tight due to worn cutting tools will severely hamper friction levels.

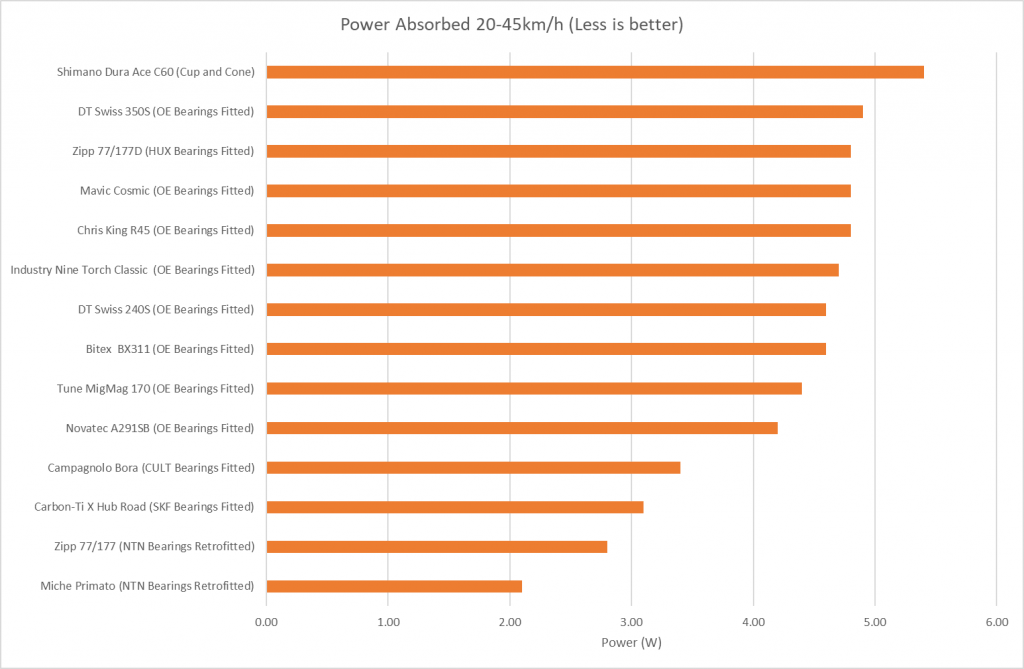

The chart below shows the friction loss through hubs which were loaded. These tests results have some limitations

- They do not take into account Road Vibration

- A sample size of one for each hub set does not take into account any natural variation

- Some of the hubs had completed an unknown mileage, they were checked for vibration to ascertain any bearing fault frequencies.

- The power figure has some factors for calculation and it’s advisable to use this as a relative reference rather than an absolute figure

Upgrading Wheel Bearings

It is not cost effective to replace OE bearings straight from the factory unless the rider requires the ultimate in marginal gains. It is more advisable to wait until the bearings have worn out first and then retrofit.

Conclusions

Generally speaking, the Hambini recommended hubset to use would be the Carbon-TI. These have low levels of friction, are well made and use decent quality bearings from the factory. The Miche Primato hubs are a good budget option but the small axle diameter is not favourable in the longer term despite having the overall lowest friction, it should be noted that the test example had retrofitted bearings so the exact figure from the factory may be higher or lower. The angular contact Shimano hubs do quite badly in this test because the contact angle lends them to high levels of axial load, these wheels will be extremely stiff and predictable when cornering but the trade off is the higher linear friction.

In the longer term, bearings will wear out and for this reason, Shimano hubs are not recommended unless the cyclist is willing and able to carry out regular maintenance. The bearing surfaces are costly to replace and are a proprietary component.

Sachin – Was looking at this graph on Weight Weenies but have to ask here because you are banned. Do you think the bitex hub set would perform similarly to Carbon Ti if retrofitted with low friction NTN or SKF bearings?

Yes BUT some Bitex hubs use non standard sizes so you end up having to use cheap no name branded bearings. Carbon ti use 6000 series on all of their hubs so you can always get them in any brand.

Which Miche hub was tested?

primato

Primato Syntesi?

it was just primato.

hello

after 14years i wanted to replace the bearings in my AmCl RD205. After unmounting the bearings i meassured the bearing landings (15267)

freewheel outer: 25,92mm

freewheel inner: 25,96mm

hub inner: 25,96mm

hub outer: 25,98mm

while a document from ntn said the tolerance need to be M5, so 25,986 – 25,995mm.

My question: if i press good bearings in this small landings, will i have some benefits?

What can I do to make the landings wider without special equipment?

That’s too small, you’ll find the bearings start to rattle quite quickly

I’ve seen a set of 2017 Zipp 202’s with 77/177 hubs at a good reduced price. Unfortunately I’ve found several poor reviews regarding the hubs, rear wheel play and flange failures. What do you think?

From experience, I’d say the hubs were rubbish.

Thank you. Your no nonsense approach is so refreshing. I’ve introduced your videos to some of my friends in Canada and they really love you. Only if you have time: I have always run alloy rims with standard Campag, Mavic or Hope hubs but in my advancing years I fancy something a bit more exotic. Saw some ZED Ultalite carbon clinchers 1200g from a UK company and was wondering if there were any questions I should be asking about the hubs in particular?

What do you think about the DT180 hubs? Where do you think they would stack up? Deciding between them and the Carbon-Ti X Road Hub. Thanks!

I would get the carbon ti

Are Carbon-ti hubs fine for a heavier rider? Thansk

it’s usually a rim limit not a hub limit

I intend change my carbon ti x-hub road SL bearing , ceramic bearing or original skf bearing are recommended ?

I would get SKF

For info: SKF stands for Svenska Kullager Fabriken= Swedish Bearing Factory. Keep it up, Maestro! /Niklas

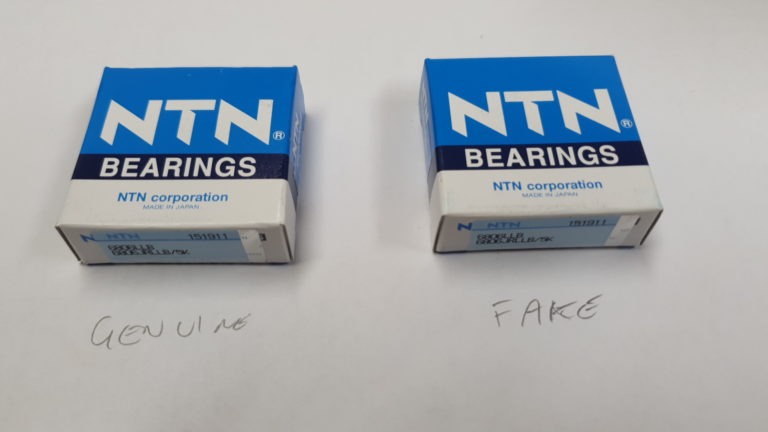

Should low tier Taiwanese bearing manufacturers such as TTN, or NBK be avoided at any cost?

personally, I would avoid them but each to their own. Their technical support is often crap.

Hambini, thank you for sharing your work on this topic. Your resources have been valuable as I’ve thought about making some upgrades and as I’ve begun to spec out my first custom build.

TLDR: – How do engagement points factor into hub speed, and should it be considered in hub selection?

I’ve seen and heard a fair amount of chat about a hub’s efficiency due to the number of its engagement points. I’ve seen this discussed as the number of teeth, pawls, or combination thereof in a hub’s ratchet system.

If memory serves, I read that a high number of engagement points was developed for benefit in mountain biking’s hilly environment. However, it has clearly become a feature that commands premium pricing in road cycling as well. Example: DT350 has an 18T ratchet while DT180 has 54, and it’s a common upgrade(?) for people to change out their 18T DT350 to either a 36T or 54T ratchet.

Does the number of points of contact meaningfully contribute to how fast a hub is for a typical urban or suburban road riding environment? Any clear benefits one way or the other for the average enthusiast rider versus a competitive racer? If it’s generally true that having more engagement points is better for performance, is there any downside whatsoever, such as maintenance or durability?

Road hubs vs MTB hubs are a different animal. You don’t really need the very small angular catch on a road bike because the gear ratios are much longer so only a fraction of turn on the pedals will engage the ratchet on a road bike. You also don’t have the on off power loading on a road bike.

So would it be wiser to chose the lower PoE given the choice between say 18 and 54 for road cycling? Or does it not impact the efficiency at all?

It makes no difference to efficiency, once it’s locked that’s it, you’ll be on the bearing friction.

Hi Hambini!

I was just wondering what rims you would rate as a good match for the Carbon Ti hubs ? and whether you think the Carbon Ti full wheelset would be worth a punt? I’m assuming it will be these hubs on their carbon rims.

Hope you can help.

Cheers!

I’d actually go for Farsports hubs now and also winspace – they are very similar to each other. Both decent tolerances and well made. If you swap the bearings out, you’ll get decent performance at a fraction of the cost.

Hi Hambini!

Please advise ball bearing size for Shimano Ultegra 6800. Plan to replace them. One more thing, which one is better steel or ceramic ball bearing.

thanks

I’m assuming it’s hubs. In which case you will need to buy loose balls. They are not a 6000 or 7000 series bearing.

Could you update the tests with powerway r13 or r36 hubs (claimed better) results. They are popular in asia context.

I would if someone sent me a set.

First, Thank you for your time and expertise on this subject.

Second, I noticed that you commented that the Zipp 77/177 hubs are rubbish. I currently have a set of Zipp 808 (2019 non-sawtooth design) wheels with cognition hubs. They have so far been flawless and seem to produce less friction than any other riders’ wheels that I have ridden with. Perhaps this is a one off. I am currently weighing options of a new wheelset or staying with what I have. Do you have any thoughts on the cognition hubs?

Hey Hambini, what do you think about 21 spoke hubs with asymmetric lacing? Also, what do you think about fulcrum/campagnolo tall flange hubs, is this the future of wheel hubs? Lastly, what do you think about the cult bearing system and or usb bearing system?

Thank you for your analysis! It looks like you measured the power absorbed by the front hubs? If so, do you know how much power is absorbed by the rear hub’s clutch mechanism when freewheeling? It stands to reason that a loud rear hub would absorb more power, by conversion of kinetic energy to sound. In my experience the quiet Shimano rear hubs (with inferior bearings) spin much longer than the substantially noisier DT Swiss hubs (with superior bearings) while freewheeling. If so, the Onyx Vesper rear hub (essentially silent, with sprag clutch) should have the least power absorbed while freewheeling.

I’m looking at replacement 15267 bearings for some DT Swiss hubs. It looks like you struggle to keep your OEM ones in stock & there’s only really one manufacturer on that list that even makes them (I know it’s because they’re bike-specific and you recommend against the brand for this reason, but I already own a few sets of hubs!)

I notice that the DT Swiss branded 15267 bearings have two different coloured seals & their instructions stipulate putting them in a specific way round. Does this mean they’re using an LLB for the internal facing seal and an LLU externally? If so, then does that make up for the advantage of switching to your recommended brand(s) with 2x LLU seals? Am I just as well getting the more readily available DT bearings with the hybrid seal types?

You are better off getting either fully sealed or non contacting seals. A hybrid approach isn’t great because the non contact side will leak grease.

“It is more advisable to wait until the bearings have worn out first and then retrofit.”

I tried speeding the wait time of my 7 year old Wheels up by removing the contact-seals of those HOPE-bearings…

After 7 years the grease inside of them still look fresh and undirty.

I doubt that removing the seals going to wear them down earlier as the endcaps makle a good job keeping dirt and water out.

But, well removing the seals and replacing with thinner “grease” (mixed Teflon-Grease with a bit Ceramic-Oil) definetly now has lower frictional losses, reasonable noticable. Its great already and NTN LLB might be better, but i doubt that its worth paying 120euros for 6 bearings… Its right. You want to wait until they are worn. For those 120 i get some molten speed wax instead to US-immerse my chain, yehaa.

THANK YOU

Alles in Obi!

if you want to trash them really quick – some salt water will do the trick!

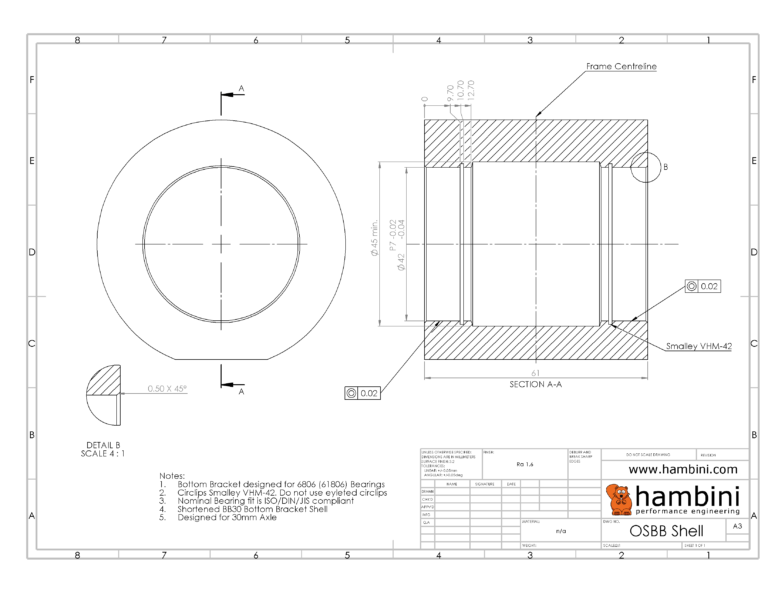

I am very interested in your opinion on this. Wheel bearings in a bike do two things – they bear the main radial load but also the axial load of locating the hub barrel. I am not aware of any hub design that separates these loads – but there was a bottom bracket design that did this: Octalink by Shimano. It used a ball bearing track to locate the spindle, and roller bearings for the radial load. Would this be beneficial from a friction perspective? A good idea for hubs?