T47 Bottom Bracket: Engineering Guide (Threadfit)

Introduction to T47

T47 was touted as a solution to a problem that should never have really existed, that of the creaking bottom bracket.

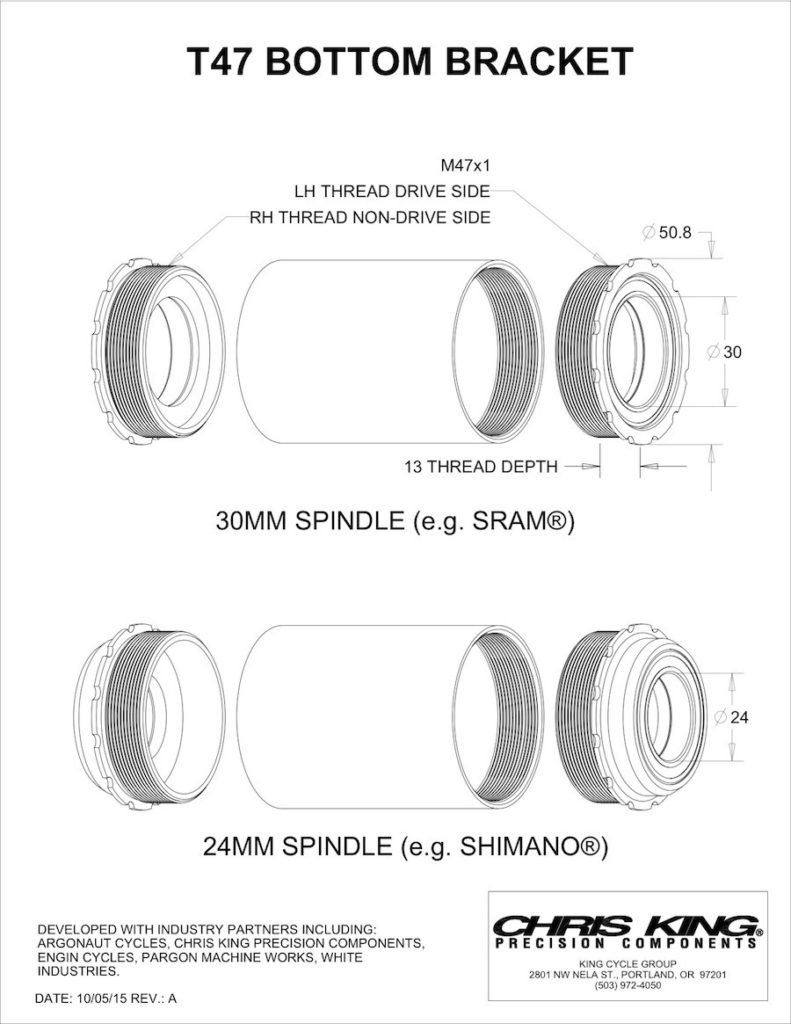

T47 was originally developed by Chris King with the assistance of some others. In short, it is a threaded version of PF30. Pressfit bottom brackets have such a bad name that some clever individual in the wankateering department decided to call it “Threadfit T47”

Hambini T47 Bottom Brackets can be found here

Creaking bottom brackets are fundamentally the result of bike manufacturers reducing their costs to the absolute minimum and neglecting some geometric locating features during the manufacture of their frames. The finished products rarely have round holes that are aligned with each other. That statement is somewhat caviler as a certain amount of ovality and eccentricity (the engineering word for out of alignment) is permitted but these manufacturers generally fail to meet these basic engineering tolerances which you would find in a typical food blender. As an example an injection molded Lego brick has tolerances that are 5 times tighter than modern bikes.

The consumer has long lived with this because they did not have the ability to check these things or were aware of them. Many bike shops also did not have the tooling or measuring equipment to check for these abnormalities. The cycling media who are effectively an extension of the big bike supplier’s marketing departments also skipped over this troublesome issue.

Fundamentally, any type of modern bottom bracket is a press fit, the bearings always press into the housing (the majority of cranksets) or press onto the crank axle (Campagnolo).

Shimano designed their Hollowtech 2 system to use 6805 bearings, this is a popular size and had a load rating that is ample for most bottom bracket bike usage. This standard was heavily patent protected and to this date the Shimano crankset system is probably the best. It uses a steel axle with sacrificial parts within the bottom bracket to prevent under rotation and corresponding grinding of the crank axle. The current crop of 30mm and 29mm DUB/AXS axles exists to try and circumvent Shimano’s patents.

The usual marketing claim of a larger diameter axle is stiffer neglects the material and bearing spacing. Almost all 30mm and 29mm (SRAM) axles are aluminum. This aluminum interfaces directly onto a hardened bearing seat which if you follow the Hambini YouTube channel will know, leads to grinding of the axle. Aluminum is much softer than steel. Aluminum is also much less stiff. There are only a few grams in it between a 24mm steel axle and a 30mm aluminum axle.

The chosen size of 30mm for aluminum axles is not a sweetspot for any engineering. It is because the next bearing size up from 6805 that will remotely take the load happens to be a 6806. The 06 indicating a 30mm bore.

In threaded applications, BSA has for a long time been the standard for bottom brackets. The geometry of this shell (1.375″ x 24TPI, approx. 35mm diameter) results in a system that is ideal for a 24mm axle – there is around 5.5mm of wall thickness but severely restricts a 30mm axle – only 2.5mm of wall thickness. Hence to allow for enough wiggle room, the T47 standard was born.

T47 allows 6mm of wall thickness which is almost exactly the same as the original 24mm/BSA combination.

However, the engineering on T47 is not without compromise.

T47 Bottom Bracket Geometry

T47 comes in a number of variants

| Designation | Drive Side | Non-Drive Side | Shell Width(mm) | Notes |

|---|---|---|---|---|

| T47-68 (T47 or T47 External) | M47x1.0 | M47x1.0 | 68 | This is a very popular standard on custom bike frames that are mainly made of metal. |

| T47-86 (T47i or T47 Internal) | M47x1.0 | M47x1.0 | 86.5 | |

| T47-85.5 (T47i) | M47x1.0 | M47x1.0 | 85.5 | This standard is unique to Trek. In most applications, it is interchangeable with T47-86. |

| T47A-77 | M47x1.0 | M47x1.0 | 77.5 (See Note) | This shell is Asymmetrical, The drive side is identical to a T47-68, and the non-drive side is identical to a T47-86. This is used almost exclusively on Felt and Factor bikes |

Disadvantages

Weight

The biggest concern for most bicycle riders will be weight. A typical T47 bottom bracket will weigh around 180g. The bike will also need aluminium inserts or a sleeve inside the frame to accept T47, the typical weight of the sleeve is about 100g. The sum of those is approaching 300g. In comparison. BB86 weighs around 95g, and PF30 weighs around 130g.

Tooling

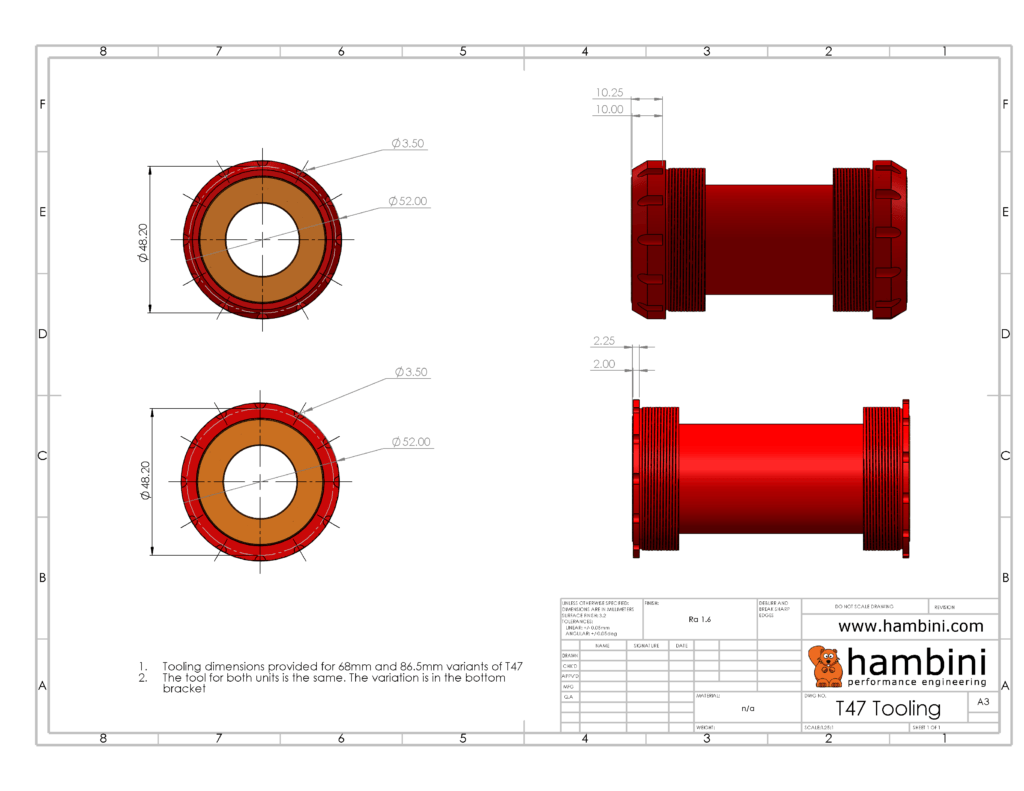

A lot has already been mentioned by other sources regarding the tooling to take the bottom brackets in and out. A particular variant of T47 has a wide 86.5mm shell (mirroring BB86) and correspondingly thin flanges for the tool to grip on to. 2mm is simply insufficient, the risk of it slipping or stripping is significant. Trek, Felt and Factor have indicated they will adopt this variant of T47.

For comparative purposes, a Chris King Threadfit T47 to Shimano is pictured below vs a Hambini T47 to Shimano. The narrow tool flanges are not required to maintain clearance to the crank, they are there to make it easier and cheaper to manufacture.

It may not be completely obvious how much of a problem tooth slippage is until it is experienced. This video from YouTuber, Rides of Japan shows the slippage problems with a Park Tool.

Advantages

An undisputable advantage of threaded bottom bracket systems is their ease of use and installation, especially for the end user. Providing the individual has the correct drive tool, it is straightforward for them to install and remove a threaded bottom bracket. They do not have to contend with out of round holes because the threaded system will not permit it. The issues around misaligned threads between sides still exist but these can be mitigated with an alignment sleeve (Hambini Bottom Brackets have this feature as standard).

In metal framed bicycles which are often found at lower price points and as custom builds, a T47 bottom bracket is ideal. The 68mm variant lends itself well to the material and construction techniques.

Performance

The frictional loss in a T47 Shimano setup is worse than a BSA Shimano setup. The main loss is through the bearings. The T47 uses the 6806 whilst the BSA uses 6805. The difference is small but measurable.

Stiffness is also a characteristic that is desirable. The BSA Shimano Setup is stiffer owing to the smaller size and more accurate absolute manufacturing tolerances. Ultimately, a pressfit solution such as BB86 is superior because some of the load is transmitted directly into the frame.

Hambini T47

A number of people have asked for a T47 bottom bracket, mainly for custom builds. At the time of writing, the 68mm version of this bottom bracket was prototyped and released after extensive testing. This bottom bracket has many features carried over from the highly successful BSA Shimano bottom brackets including the tight-fitting center sleeve, tier one bearings and the precision engineering that has become synonymous with the brand.

Watch on YouTube

You can watch the full video on this subject on youtube

Do you have T47-68 for SRAM DUB (ya… I know, but…)?

I can make you one to order.

Can it be used on an asymmetric T47 frame like the Factor Ostro?

That bike needs a special version of T47. It doesn’t comply with the standards laid out.

Ok, thanks. Is there any technical/functional advantage going for an asymmetric T47 design over the symmetric one?

Chris King (which usually has heavier BBs) T47 30x and T47 24x are 120g and 134g, respectively, so they’re definitely heavy but not the 180g as stated above:

https://r2-bike.com/CHRIS-KING-Bottom-Bracket-ThreadFit-T47-30X

https://r2-bike.com/CHRIS-KING-Bottom-Bracket-ThreadFit-T47-24X

Also Trek has decided to go with 85.5mm wide shells specifically to combat the issue of tool engagement:

https://cyclingtips.com/2019/06/trek-t47-threaded-bottom-brackets/

On the Trek, The extra 0.5mm is not going to do much for tool engagement. The video shown was on a Trek bike. The engagement is too small.

Regarding Chris King. The centre section of that is plastic, not metal and the outer has it’s teeth engagement section reduced to a minimum. You can either have the extra material or a stripped BB.

Hambini, would you explain, how the bigger BB leads to a reduction in stiffness? I remember, you were mentioning the Look BB65 being exceptionally stuff due to its large bearing arrangement.

The bearings are the same width. In this case 7mm as a 6805. So the ball diameter is the same. The difference is the distance from the centre of the axis so you end up with a longer distance and thus a longer lever arm. If you apply the same amount of lateral force, the defelction is higher because the torque is higher. Hence it’s less stiff.

Have you considered developing a crankset, given the less than ideal solutions on the market? Yes, Shimano axle / bearing standard is good, but Hollowtech delamination, outright failure and DS PM problems rather less so. Also, potentially, for the unfortunately increasingly popular T47, you could perhaps engineer a way to further ameliorate the inherent increased drag as described in the article, in a T47 version. Maybe moulded carbon arm with 110BCD 4S compatible fitment so that third party spider PMs could be fitted, or collaborate with Sigeyi or Xcadey to offer one as a ‘factory’ solution?

The current Rotor crankset is very good, It doesn’t have hollow arms so that business about delamination has gone. Shimano are by no means infallible but I’d say their engineering was better than the vast majority out there.

Would you say the Rotor crankset is the best you are aware of currently? All Rotor cranksets or a specific one?

The one that was reviewed was very good. If the others in the range are if the same design then I would have no hesitation in getting one.

How important is ovality in a T47 shell? I just received a top-of-the-line custom titanium bike frame, and the bottom bracket minor diameter seems to vary between 45.95mm and 46.61mm. (Official spec is 45.94+0.15mm.) Is this something that would cause issues?

you may find it binds or winds in eccentrically.

Thanks – do you have any plans to make a 30mm T47-86.5mm BB?

The only argument my frame builder (American) has against your BB is that Chris King make their own bearings. In the US they are seen as fairly magical. Bolstered by the fact they aren’t sold on to third parties. What’s your take on this? I’ve never had trouble with Chris King anything but is their “drop forged” bearing tech really ahead of the rest?

I don’t think Chris King can really be compared with NTN and SKF for technical ability.

Hello Hambini Admin.

Please could you clarify for me the statement “The issues around misaligned threads between sides still exists but these can be mitigated with an alignment sleeve”? I’m struggling to visualise how threads can be misaligned or what issues might occur.

Whatever the reason, how does a central sleeve in the BB help whatever issue misaligned threads bring about?

Thank you!

Threads have a small amount of play in them to facilitate tightening and loosening. A central sleeve that has a tighter clearance than the the screw thread clearance will facilitate better alignment. On a more general note, bolts/screws etc are considered fastening features and not locating features. Spigots, dowels etc are considered alignment and positioning features. you generally shouldn’t try and do both criteria on one feature. I would suggest watching the BSA video as this shows how the central sleeve works.

T47 is considered to be more stiff / make it easier to produce frames with higher lateral stiffness compared to BSA bottom brackets. The reason given for this increased stiffness is the larger diameter of T47.

Are you doubting this or are you saying that there is another effect (the effect of the bearings you described) that offsets the larger diameter of T47 so that overall BSA bottom brackets lead to stiffer frames vs T47?

I’ve read the article with great pleasure, but i realised that my combination of bike and crank is not favourable. I ride a alloy Nicolai Argon Road with BSA threads, and last year i’ve purchased titanium Cane Creek EE-wings all-road crankset with a 30mm axle.(i got fed up with carbon cranks failing). Both Frame and crank are bombproof (that’s what i look for) and wel engineered and wel manufactured in my opinion, so i would like to stick with them. But now i need BSA bearings for a 30mm axle, and you don’t make them…for a good reason as i’ve read above. After being a Chris King user, i tried the Ceramic Speed last year, but they failed miserably. So two questions for you: can you make a solution to order for my situation? And if not: which bottom bracket would you recommend when you keep durability and build/sealing quality in mind?

I will have a BSA to 30mm setup available at the end of the month. It’s not perfect but it’s borderline passable and gives people an option.

That’s good news! I understand that with only 2.5mm wallthickness to play with, the options for a sturdy left-right connection are limited. But i trust your engineering skills and honesty, that it will be better then all the current options on the market (otherwise you wouldn’t bring it to the market in the first place). Can i pre-order a set or get a notice when they’re for sale? I would like to hear how to proceed. Thanks!

Any news on the BSA to 30mm setup yet? (i know. I’m an impatient f**k)

Hi i still newbie in this topic, How about if i want to change my old bearing into NTN 6806 LLB 30x42x7 Ultra Low Friction Seal BB30 is it fit with the T47 bottom bracket size?

It is on a Hambini BB

I’m still trying to figure out what reliable tool to buy to remove the T47 from my Bombtrack Audax.

When I removed the spindle due to a click it was almost dry on a new bike. No click now but I wonder how dry the T47 threads are?

Confusing for this relatively new bike mechanic when I read Bombtrack, Park, King, WM etc.

unfortunately there is no universal spline drive pattern yet.

@Steve – I need to service the BB on my Bombtrack Hook. Did you ever find a good tool to remove the BB? Bombtrack make one, but would need to ship from Germany.

In regards to the statement in the article “The frictional loss in a T47 Shimano setup is worse than a BSA Shimano setup. The main loss is through the bearings. The T47 uses the 6806 whilst the BSA uses 6805. The difference is small but measurable.”, I have the following question:

For a Shimano Crankset (or other 24 or 24/22 mm variants), why not design the T47 with a 6805 bearing instead of a 6806?

You could very well do that but it would increase the weight and there would be a loss of stiffness. If a 6805 were to be used, it would actually be better to use a BSA bottom bracket.

Thanks Hambini. I always enjoy your channel. You get straight to the point. I owned Trek’s with BB90. I thought it ok but then I had the problems (both on top line frames from them).

Even my dealer doesn’t understand the root of the problem. I’ve walked away from them now.

It’s when Ioojec

I am designing my own titanium frame, so I have to decide whether to go for BB386EVO or T47. BSA is not an option because I run SRAM cranks with Quarq power meter. In theory BB386EVO is superior, but I guess that T47 might be better because it allows a larger error margin. The BB386EVO shell might bend slightly while welding the down tube, seat tube and chainstays…what’s your opinion?

on a metal frame, a threaded cup ie t47 is a better option.

Thank you. Assuming a T47 shell with your BB for DUB cranks installed, what is the diameter of the metal sleeve that joins the two sides of the BB? I guess it might interfere with the hydraulic tube and the rear derailleur cable housing (mechanical shifting). This would not be a problem for carbon since the space inside the BB shell is usually massive, but in my case it’s going to be a titanium frame (meaning less space inside BB shell).

36mm, The shell diameter on Ti tube would be 47mm to cope with the threading. That leaves 11mm spare, Hoses are typically 5mm so it will go around.

Perfect, thank you

I forgot to ask you how long each threaded side of the bb is (possibly about 15-20mm?). I need this info to decide where to weld the chainstays, considering also internal cable routing.

Hallo mister Hambini,

I was wondering if there will be a bottom bracket T47 68 ultra torque available in the near future? (Also with a 36mm sleeve for internal routing in my Ti frame) I’am aware you dislike campi spacer system. Thanks in advance. Greetings from the Netherlands, Xander

I’m working on campagnolo fitments at the moment. THey’ll take a few months to filter through.

13mm threaded section

Do you know of the seka Exceed RDC frame man? Seems to be copying a Factor VAM Ostro (?).. with T47.. Would you sexy bottom (bracket) be a good fit?

https://cycling100.com/products/seka-road-bike-frame-exceed-rdc-red?variant=41610181116099

Would love it if you could get one to review, too

You’d need one of these, https://www.hambini.com/product/t47-86mm-threadfit-shimano-racing-bottom-bracket/ It has been used by other individuals with no issues reported.

So…. PF30 may be superior to a T47 in a Ti frame where the origin of the problem is eradicated (being mass production carbon) ?

So no need to pay $250 to “upgrade” on a new Litespeed frame?

I have a CK T47 24X bottom bracket. Bike and BB are less than 1year old and bb is creaking. Will your bb cure this? I put one of your press fit bbs in my wife’s Cervelo last year and it’s fantastic

Dear Mr. Hambini,

I have a 2021 Lynskey Helix Disc Road frame with an BSA English threaded 68mm BB shell. My question is, can I still use my SRAM Force Crankset on a T47 BB gravel bike frame? Is there an adapted BB system that you make to allow usage of my SRAM Force eTap components in a newer gravel bike frame without having to buy a new crankset? Thanks so much and I love your channel and engineering expertise!

By any chance, do you know which bottom bracket Megamo uses, they do not mention it anywhere on the site for the JAKAR 30. Do you recommen i stay away from b47 assymetrical bottom brackets from felt?

I don’t know what Megamo uses. T47 is okay provided the alignment between the left and right sides are okay. We are starting to see a lot of frames where the two halves are misaligned.

The Look 765 Optimum has a 85.5 BB width. Does this require the Trek spacers with the T47?

its generally within the normal range as it’s +/-0.5mm however in my experience, Look threaded BB tolerances for T47 can be quite erratic.

Great thanks, I have an Ibis with what looks like t47, in the process of getting the the crank out to replace the bearings, ( I hear crunching/grinding when climbing). This info will help me on the way. Novice mechanic.

I’m a bit confused. I have a Trek Domane SL5 2021 with Shimano 105 cranks which are 24mm in diameter.

You state in the article above that Shimano uses 6805 bearings, but these bearings have 25mm ID. There would be too much play between shaft and bearing. Am I missing something?

My BB is a Threaded Praxis M47-I.B 85.5mm with cheap enduro MR 2437 LLB (24x37x7) bearings, and I would like to replace them with high end NTN 6805 (25x37x7) bearings, but the ID seems wrong.

Is some sort of 1mm shim needed if I want to switch to 6805 bearings?